- Home

- Sheet Metal Leveling Machine

- ADV LG80

ADV LG80

Product Description

ADV LG80 series hydraulic parts leveling machine (Material circulation system)

The metal parts leveling machine adopts a hydraulic drive system to provide powerful correction force and stable pressure output, ensuring that the flatness and shape accuracy of the parts meet strict standards. This is especially important for parts that require high-precision assembly and performance.

Machine Parameters

|

No

|

Model

|

ADV LG80-500

|

ADV LG80-1000

|

ADV LG80-1300

|

ADV LG80-1600 |

|

1

|

Roller diameter

|

80

|

|||

|

2

|

Roller number

|

19 | |||

|

3

|

Nominal leveled width

|

500mm

|

1000mm

|

1300mm

|

1600mm |

|

4

|

Rated plate thickness

|

2-6mm

|

2-6mm

|

2-6mm

|

2-6mm |

|

5

|

Max. plate thickness

|

15mm

|

|||

|

6

|

Leveled precision

|

K

|

|||

|

7

|

Applicable

|

strip steel, sheet metal, etc

|

|||

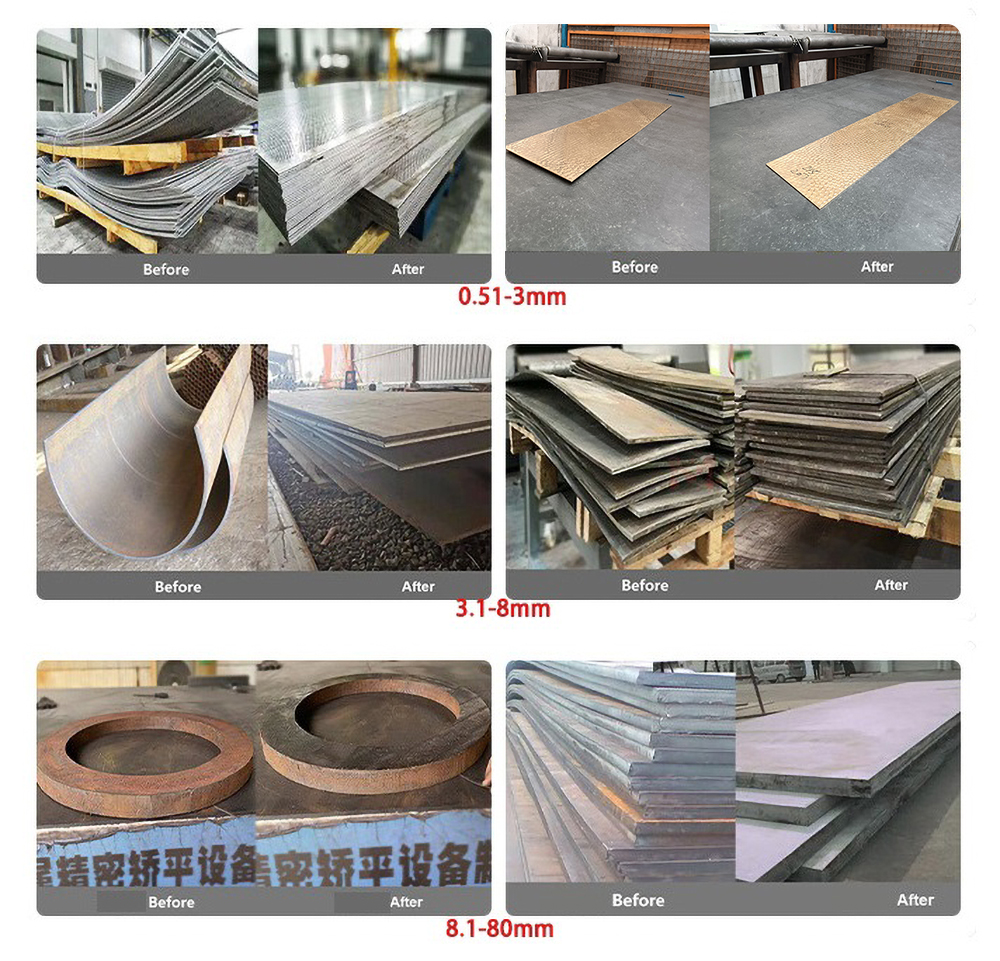

Application industry and sample

More Info

Features of hydraulic high-precision leveling machine

1. High-quality support rollers with long service life

Reasonable number of support rollers, strong support, can repeatedly achieve stable leveling effect, and improve the service life of support rollers

2. Hydraulic system, better leveling effect

Hydraulic control device, better leveling results and constant, hydraulic system installed with pressure-maintaining valve, the system stops working, greatly reducing equipment energy consumption and equipment noise

3. Welded steel structure roller frame, anti-twist

It can level high-strength steel. The upper and lower roller frames are connected by four columns, which is different from the traditional frame beam structure to ensure overall high rigidity

4. Leveling roller surface polishing treatment

Ensure that the surface of the parts is not damaged during the leveling process

5. Operating system, more intelligent

Visual operation, providing precise settings, the equipment is equipped with a 10-inch touch screen as standard, the operation interface is simple, professional program is quickly set, the data display range is 0.01mm, and remote service is optional

6. Machine tool design, customizable

One side is equipped with a large movable door with an observation window, which is easy to contact and observe the internal mechanism of the machine tool. The operation is simple, and the operation button is installed at the inlet and outlet. The body color and the position of the operation panel can be customized as needed