ADV 106-H4-12

Product Description

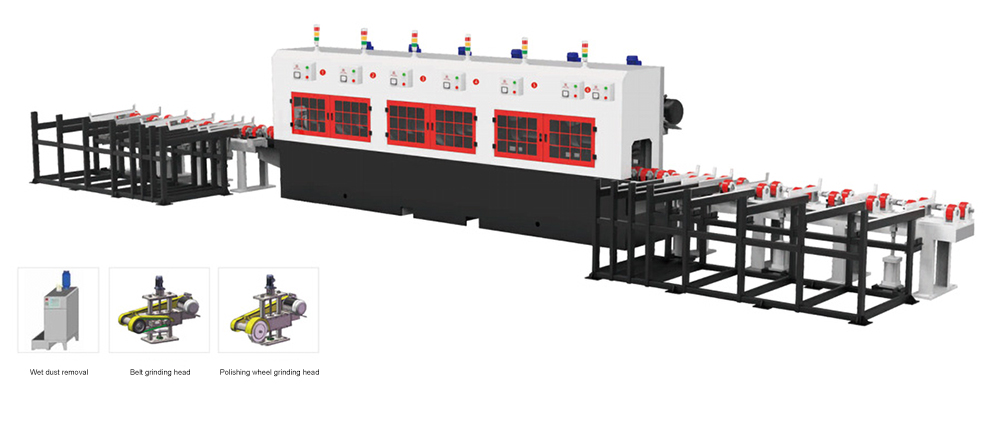

Multi-station round tube finishing machine with automatic conveyor system

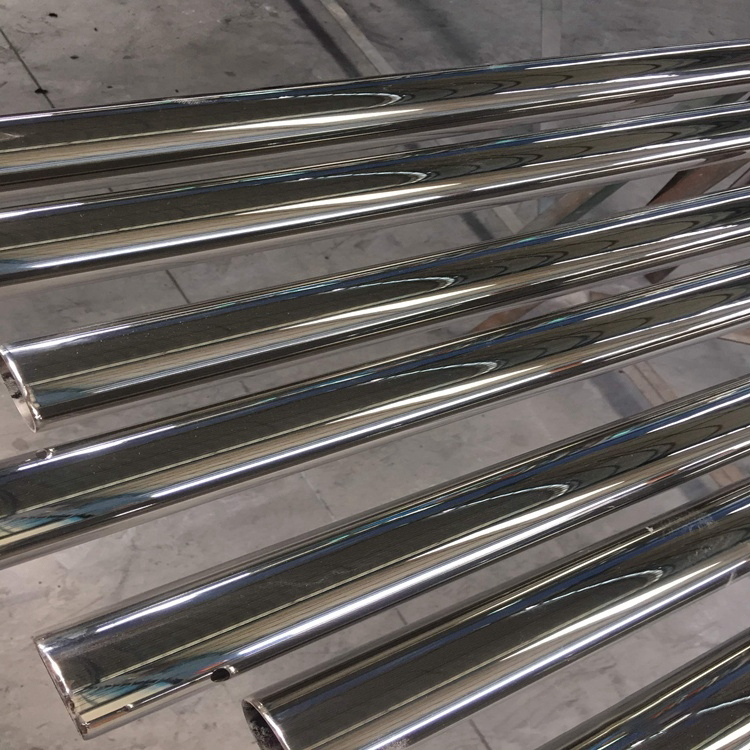

This equipment is used for polishing and finishing (matte, mirror) the outer surface of round tubes within 12m. It can automatically adjust the distance between the grinding head and the guide wheel according to the diameter of the tube, and has the function of automatic compensation for abrasive loss. According to the customer’s requirements for the surface roughness and finish of the workpiece, you can choose abrasive belts or polishing wheels. Multiple groups of grinding heads can also be used in combination.

Machine Parameters

| Machine type | Standard | Heavy duty |

| Applicable diameter | 15-60mm | 30-120mm |

| Processing length | 200mm-12m | 500mm-12m |

| Number of workstations | 4-12 Optional | 6-16 Optional |

| Sand belt size | 1880*50mm | 2100*75mm |

| Polishing wheel size | 300*50mm | 350*75mm |

| Main motor power (single) | 3kw-4kw | 5.5kw-7.5kw |

| Conveyor motor power | 1.5kw | 3kw |

| Lifting motor power (single) | 0.2kw | 0.2kw |

| Lifting type | Individual control/all joint control, automatic compensation of abrasive loss | |

| Lifting guide column direct | 60mm*2/set | 100mm*2/set |

| Polishing type | Dry polishing/wet polishing optional | Dry polishing/wet polishing optional |

More Info

Due to the large diameter and long length of the pipe, in order to reduce the bending and shaking of the pipe during polishing and obtain good finish, this machine adopts compression feeding. During operation, the grinding head motor drives the sanding belt or polishing wheel to rotate at high speed, and the pipe is fed along the length direction. Through the friction between the polishing material and the workpiece surface, the purpose of reducing the surface roughness and improving the surface gloss of the workpiece is achieved. The grinding head speed and the feeding speed of the pipe can be adjusted by the frequency converter.