ADV 508-HR

Product Video

Product Description

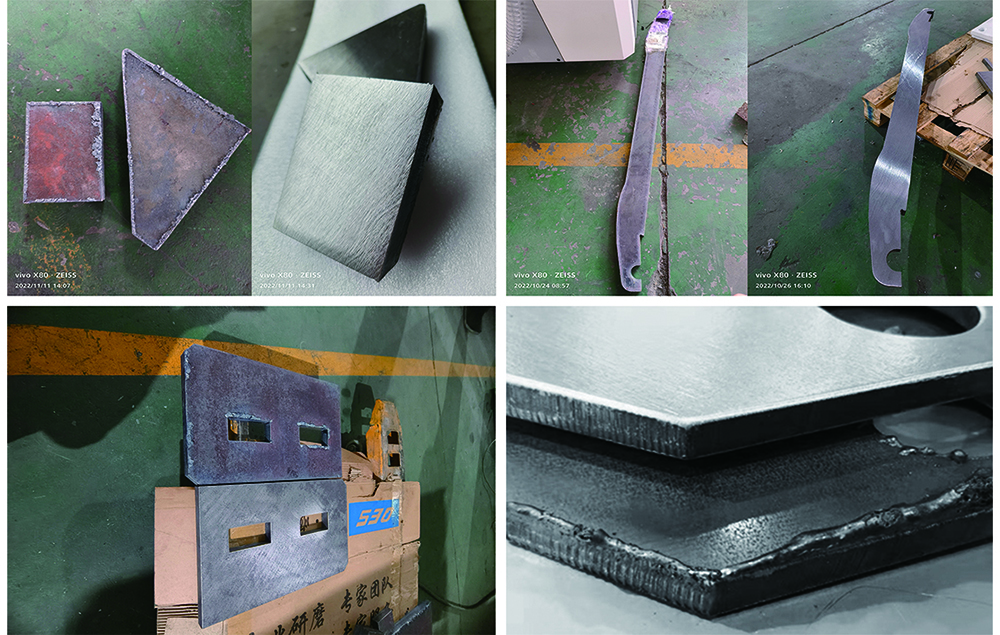

During the thermal cutting process (plasma, flame cutting), there will always be some slag left on the steel plate. Large pieces of metal slag will cause uneven metal surfaces, so they must be removed.

The ADV 508-HR series is used for heavy slag removal and deburring of thick carbon steel plates.

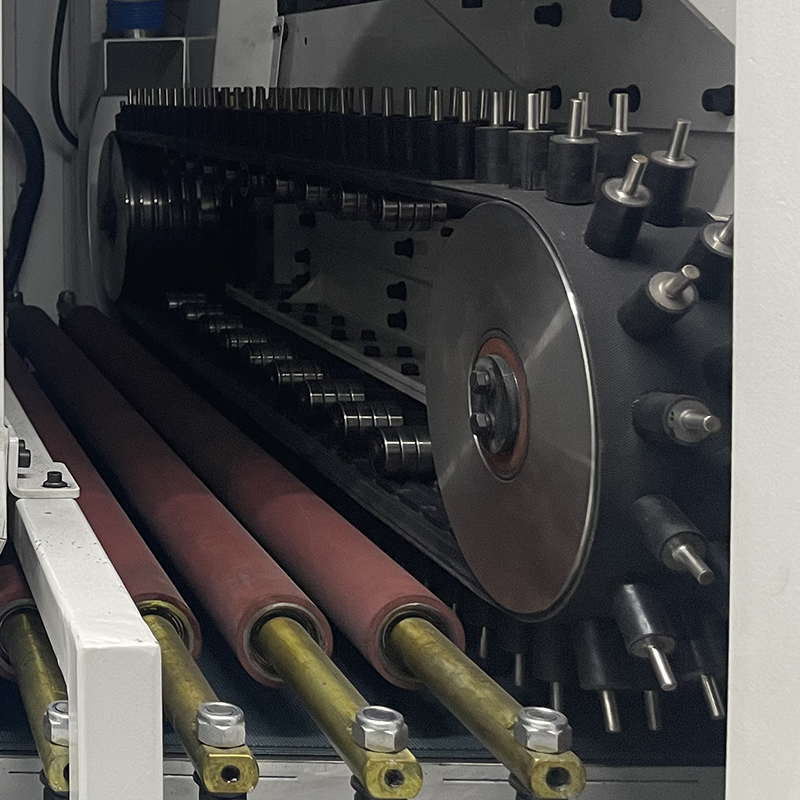

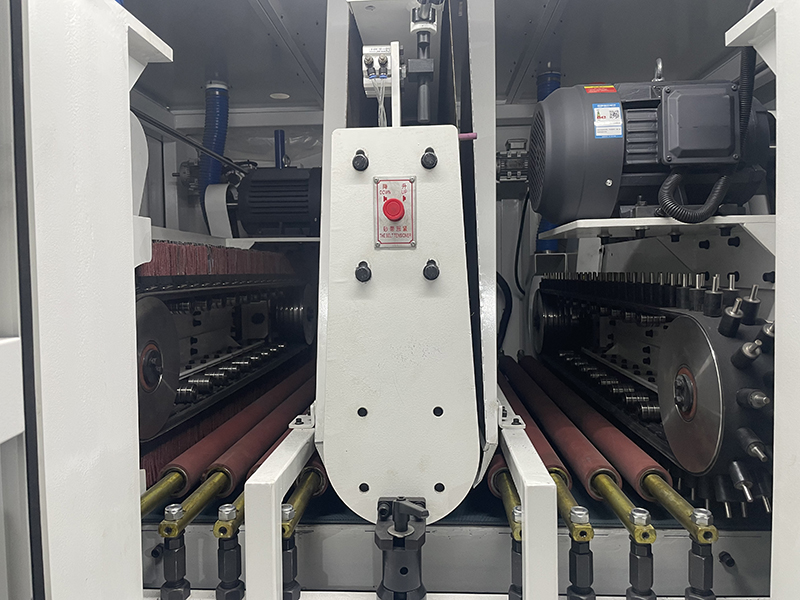

This equipment is equipped with 2 sets of slag removal hammer structures.

PLC touch operation, built-in LED light source.

Strong magnetic conveying platform, can process small parts.

Optional wet dust collector to absorb dust during work

Machine Parameters

|

Model

|

ADV 508-HR800 heavy slag removal metal deburring machine

|

|

Effective processing width

|

30-800 mm

|

|

Processing thickness

|

0.5-100mm

|

|

Minimum Machinable Size

|

30*30mm

|

|

Belt size

|

2000*820mm

|

|

Conveying speed

|

0.5-8m/min frequency control

|

|

No.1 motor power

|

2.2*2kw(cleaning hammer or sand block)

|

|

No.2 motor power

|

11kw(abrasive belt)

|

|

Conveying motor power

|

1.5kw

|

|

Vacuum adsorption motor power

|

15 kw(optional)

|

|

Total motor power

|

37kw

|

|

Machine size

|

3200*1800*2400mm

|

Application industry and sample

* The slag formation does not look attractive nor professional from an aesthetic point of view.

* The metal slag makes it difficult to apply an adhesive coating to the surface.

More Info

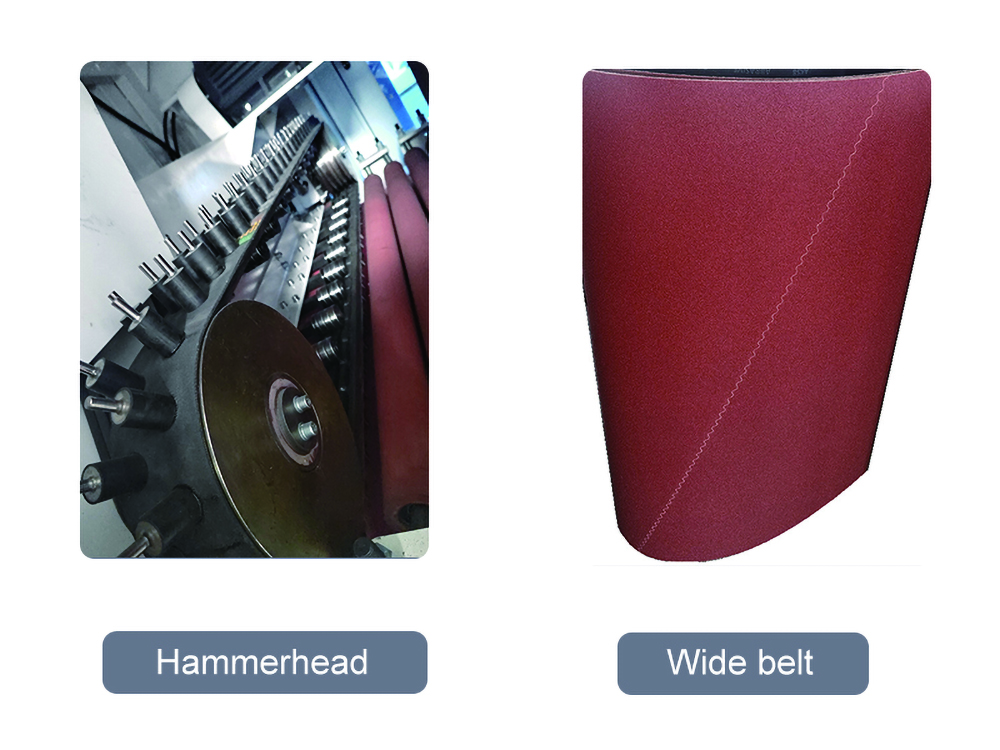

Hammerhead: The cleaning hammer rotates at high speed, knocks on the workpiece surface, cleans the workpiece surface and surrounding contours, and removes slag from the edge of the metal plate

Wide belt: Deburring and rust removal of large areas of metal parts surfaces