ADV 508-M300

Product Video

Product Description

Features of the ADV 508-M300 deburring machine

Three to four times faster than manual deburring

High-damping rubber belt, dust box extraction outlet

Hammer pin disc for heavy slags, Deburring disc for edge rounding

Sanding disc for removing of rough burrs

Vacuum or strong magnetic platform, which can process small parts

Manual deburring machine with vacuum table

Deslagging

Deburring

Edge Rounding

Oxide layer removal

Polishing

Machine Parameters

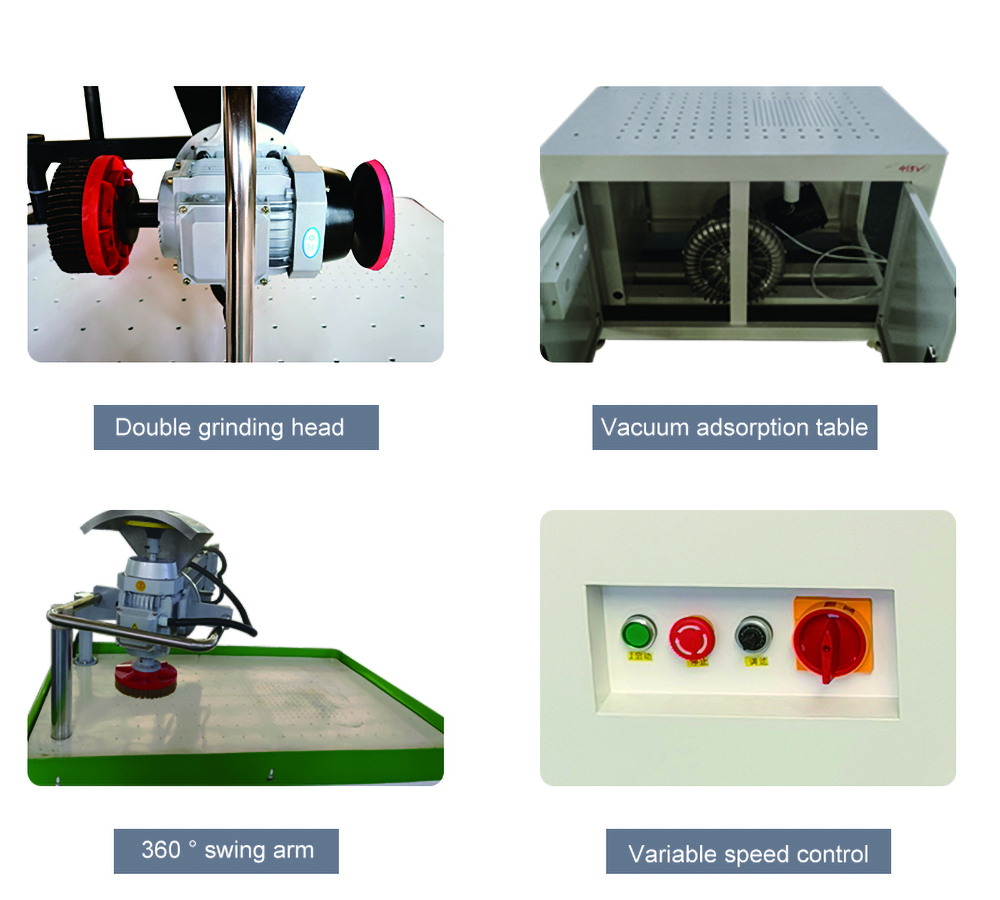

1. Product name: Flexible swing arm manual deburring and edge rounding machine

2. Vacuum area: 300*300mm

3. Working head power: 0.75kw

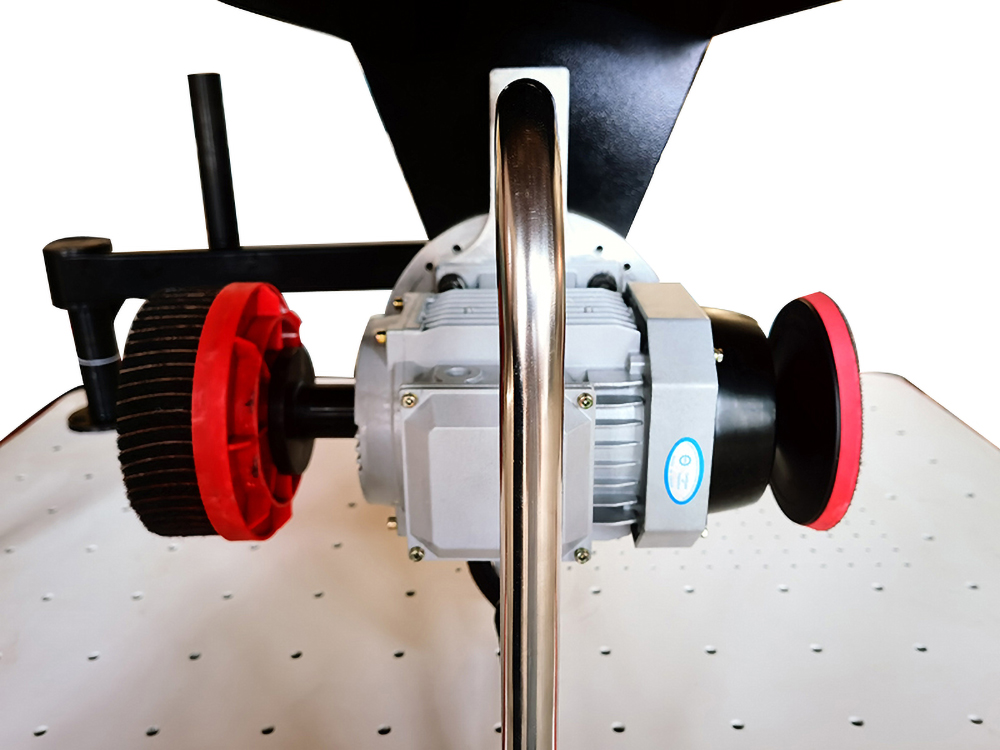

4. Number of heads: 2

5. Head types: Disc brush | Polishing pad

6. Dust extraction capacity required: 1000m3/h

7. Swing arm span: 1500 mm*360°

8. Maximum part dimension: 1200*750 mm

9. Available thickness range: 1-150mm

10. Total power: 4.5kw

More Info

Hammer pin disc: remove heavy slag and dross from plasma or flame cut sheet metal parts.

Steel wire disc: remove the oxide layer on the cutting surface

Deburring disc: remove minor burrs and edge rounding

Sanding disc: remove rust and burrs on the metal surface

Wool pad: High gloss, mirror effect

Suction cup: Self-adhesive design allows for quicker and easier installation and removal of sandpaper and wool pads