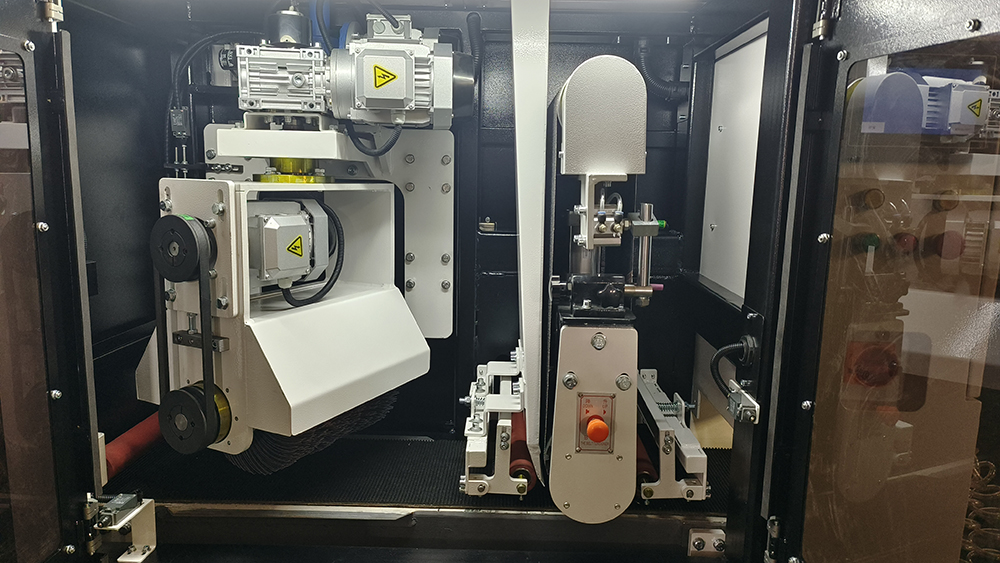

ADV 508-RW300

Product Video

Product Description

ADV 508-RW300 Economy model

The RW300 series is equipped with abrasive belts and brushes, which is very suitable for deburring, edge rounding, and finishing of small parts, and subsequent welding and painting are carried out effectively. When the wire brush is replaced at the W station, the laser oxide on the cut surface can be removed.

Compact Sheet Metal Edge Deburring Machine

Deburring

Edge rounding

Oxide removal

Finishing

Machine Parameters

1. Maximum processing width: 300mm

2. Processing thickness: 0.5-80mm

3. Minimum processing size: ≥50×50mm

4. Feeding speed: 1-6m/min

5. Roller brush speed: 4-20r/s

6. Revolution speed: 4-12r/s

7. Total power: about 11.5KW, actual operation is about 8kw

8. Abrasive belt size: 1650x300mm

9. Abrasive brush size: Φ300x400mm

10. Rounding range: R (0.1-0.5)

11. Machine weight: 1.2t

Application industry and sample

Rail transit, automobiles, construction machinery, agricultural and forestry machinery, electrical manufacturing, elevator manufacturing, household appliances, food machinery, textile machinery, tool processing, petroleum machinery, food machinery, kitchenware and bathroom, decorative advertising, laser external processing services and other machinery manufacturing Processing industries.

More Info

Features:

Small size, compact design, easy maintenance, economical price

Strong vacuum adsorption capacity, can adsorb parts as small as 50*50mm

Wire brushes for laser oxide removal

Automatic compensation and replacement reminders for abrasives

It has functions such as deburring, edge trimming, finishing and laser oxide removal for different materials.