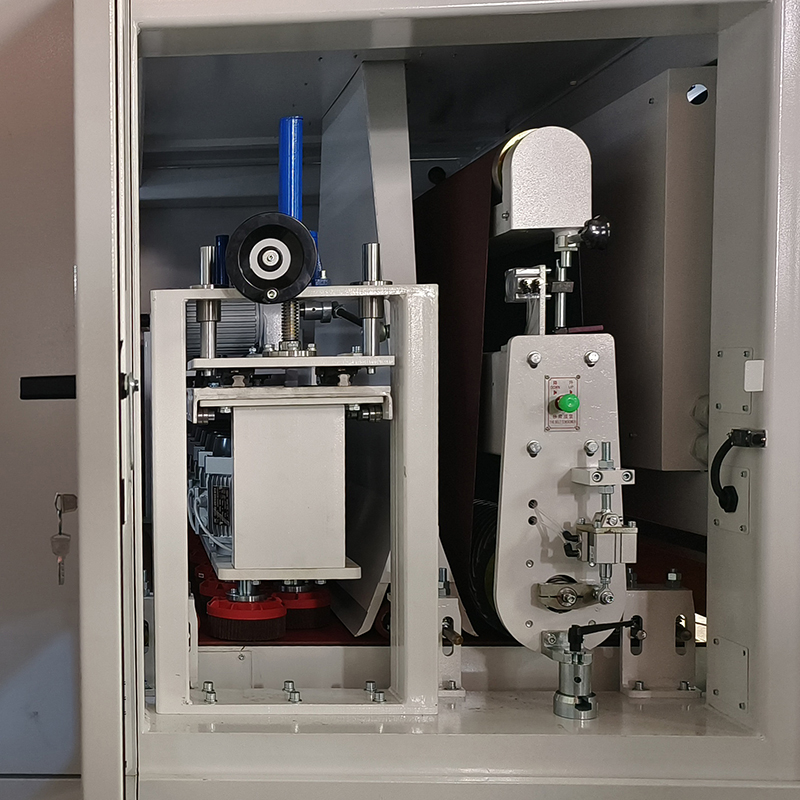

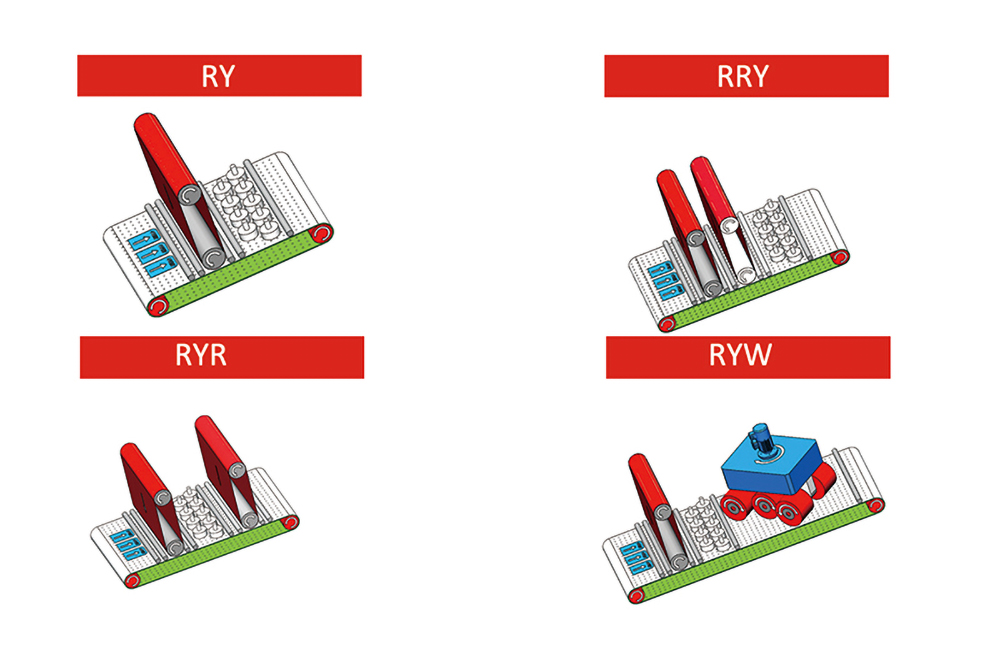

ADV 508-RY

Product Video

Product Description

Features of the ADV 508-RY deburring machine

Used for removing large burrs / slag or surface polishing effect

The disc brush is evenly ground to improve the service life of abrasives

Disc brush control system to ensure consistent parts processing effect

PLC touch operation, and the equipment has built-in LED source

Vacuum or strong magnetic conveying platform, which can process small parts

Optional wet dust collector to absorb dust when working

Automatic deburring machine for die stamping and precision parts

Deslagging

Deburring

Edge rounding

Oxide removal

Machine Parameters

| Model | ADV 508-RY450 | ADV 508-RY630 | ADV 508-RY800 | ADV 508-RY1100 | ADV 508-RY1300 | ADV 508-RY1500 |

| Effective processing width (mm) | 30-450 | 30-630 | 30-800 | 30-1100 | 30-1300 | 30-1500 |

| Processing thickness (mm) | 0.5-100 | 0.5-100 | 0.5-100 | 0.5-100 | 0.5-100 | 0.5-100 |

| Minimum workpiece size | Magnetic suction 30*30 mm, Vacuum suction 50*50 mm | |||||

| Abrasive belt linear speed (m/s) | 3-15 | 3-15 | 3-15 | 3-15 | 3-15 | 3-15 |

| Number of disc brush | 3 | 5 | 7 | 11 | 13 | 15 |

| Conveying speed (m/s) | 0.5-7 | 0.5-7 | 0.5-7 | 0.5-7 | 0.5-7 | 0.5-7 |

| Abrasive belt motor power | 7.5 kw | 15 kw | 15 kw | 18.5 kw | 22 kw | 22 kw |

| Disc brush motor power | 1.1 kw*3 | 1.1 kw*5 | 1.1 kw*7 | 1.1 kw*11 | 1.1 kw*13 | 1.1 kw*15 |

More Info

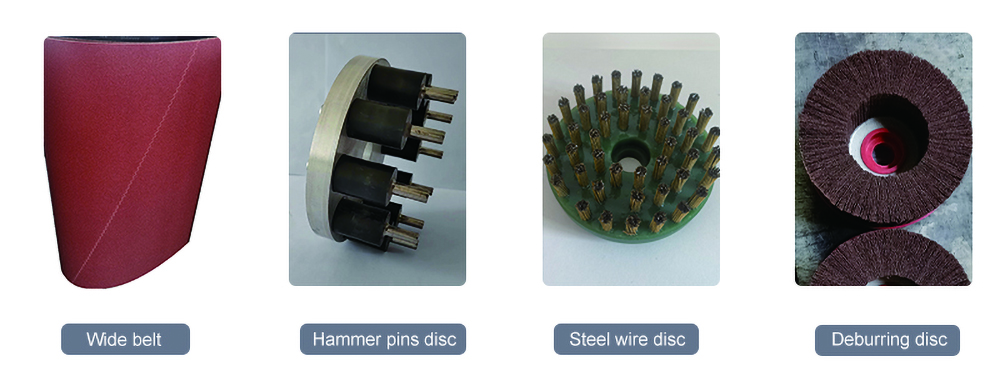

Wide belt: deburring large areas at one time for metal parts surface

Hammer pin disc: remove heavy slag and dross from plasma or flame-cut sheet metal parts.

Steel wire disc: remove the oxide layer on the cutting surface

Deburring disc: remove minor burrs and edge rounding