Wide Belt Metal Sander 300mm

Vídeo del producto

Descripción del Producto

Wide belt metal sander | Abrasive belt grinding unit

1. Improve production efficiency: The equipment can polish multiple metal parts of the same thickness at the same time, and we also have different width models for you to choose from. Under the premise of ensuring the highest quality, control your costs. This model is a 300mm wide economic model

2. Ensure product quality: The metal surface polishing machine achieves fine polishing of the workpiece surface by accurately controlling the gap and pressure between the grinding unit and the workpiece, ensuring stable and consistent product surface quality.

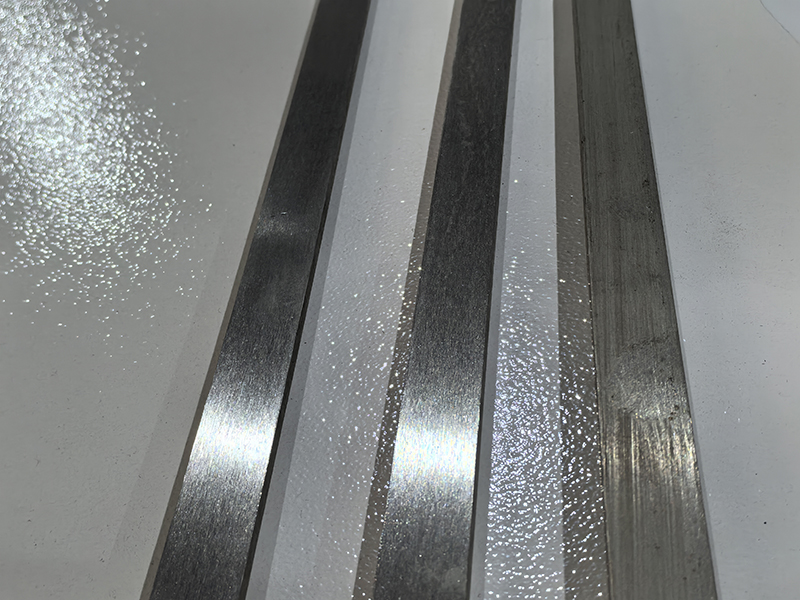

3. Strong adaptability: The wide belt polishing machine is suitable for polishing workpieces of different materials and shapes (plates, flat steel, square tubes, etc.). You only need to replace the abrasive belts to meet the polishing needs of different workpieces.

4. Easy to operate: The wide belt sanding machine is easy to operate. You only need to measure the thickness of the workpiece to achieve batch polishing operations. It is easy to master and operate.

5. Energy saving and environmental protection: The wide belt sanding machine can be connected to an industrial wet dust collector, which is beneficial to environmental protection

Parámetros de la máquina

| N0 | Artículo | Especificación | Function and use |

| 1 | Modelo | ADV 508-RR300 | |

| 2 | Ancho disponible | 0-300mm | Customizable width |

| 3 | Espesor disponible | 0,5-100 mm | Maximum opening can be customized |

| 4 | Minimum processing size | ≥30*30mm | Magnetic platform |

| 5 | Velocidad de alimentación | 1-5m/min | VFD speed regulation |

| 6 | Abrasive belt speed | 8-15m/s | VFD speed regulation |

| 6 | Abrasive belt motor | 4*2kw | Double station abrasive belt |

| 7 | Motor de elevación | 0,37 kw | For platform lifting |

| 8 | Feeding motor | 1,5 kw | For transporting workpieces |

| 9 | Sanding belt size | 1650*320mm | |

| 10 | Total motor | 9.87kw |

Industria de aplicaciones y muestra.

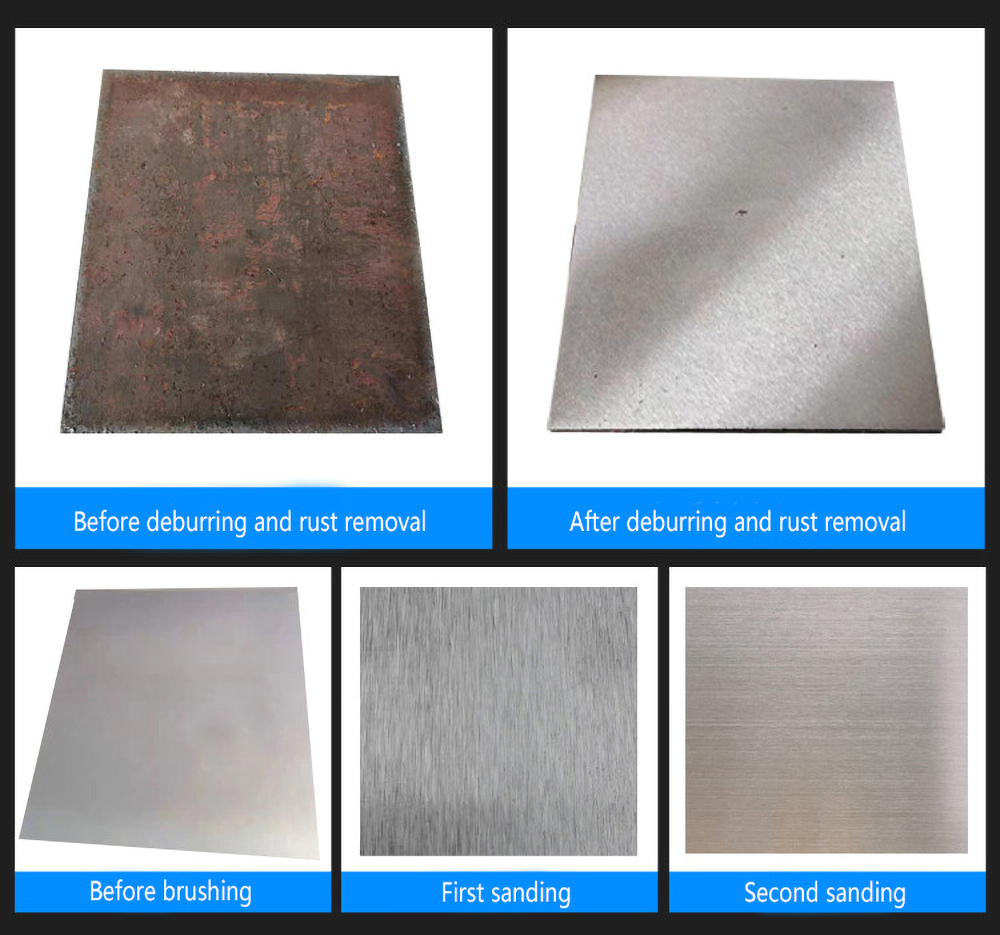

Wide belt metal sanders are widely used in deburring, grinding and finishing of flat metal sheets (aluminum, copper, stainless steel, etc.), and for removing longitudinal burrs of laser cutting, stamping and water jet cutting workpieces. They are very popular in the metal processing industry.

Enviar Consulta

SUSCRIBIR

BOLETIN INFORMATIVO

haga clic aquí para dejar un mensaje