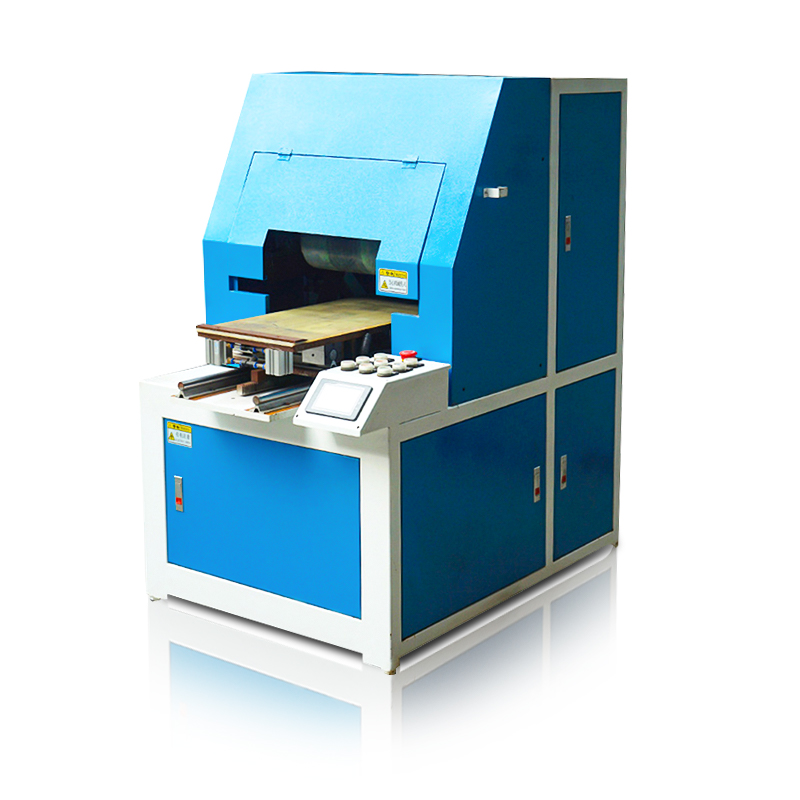

ADV 503

Product Video

Product Description

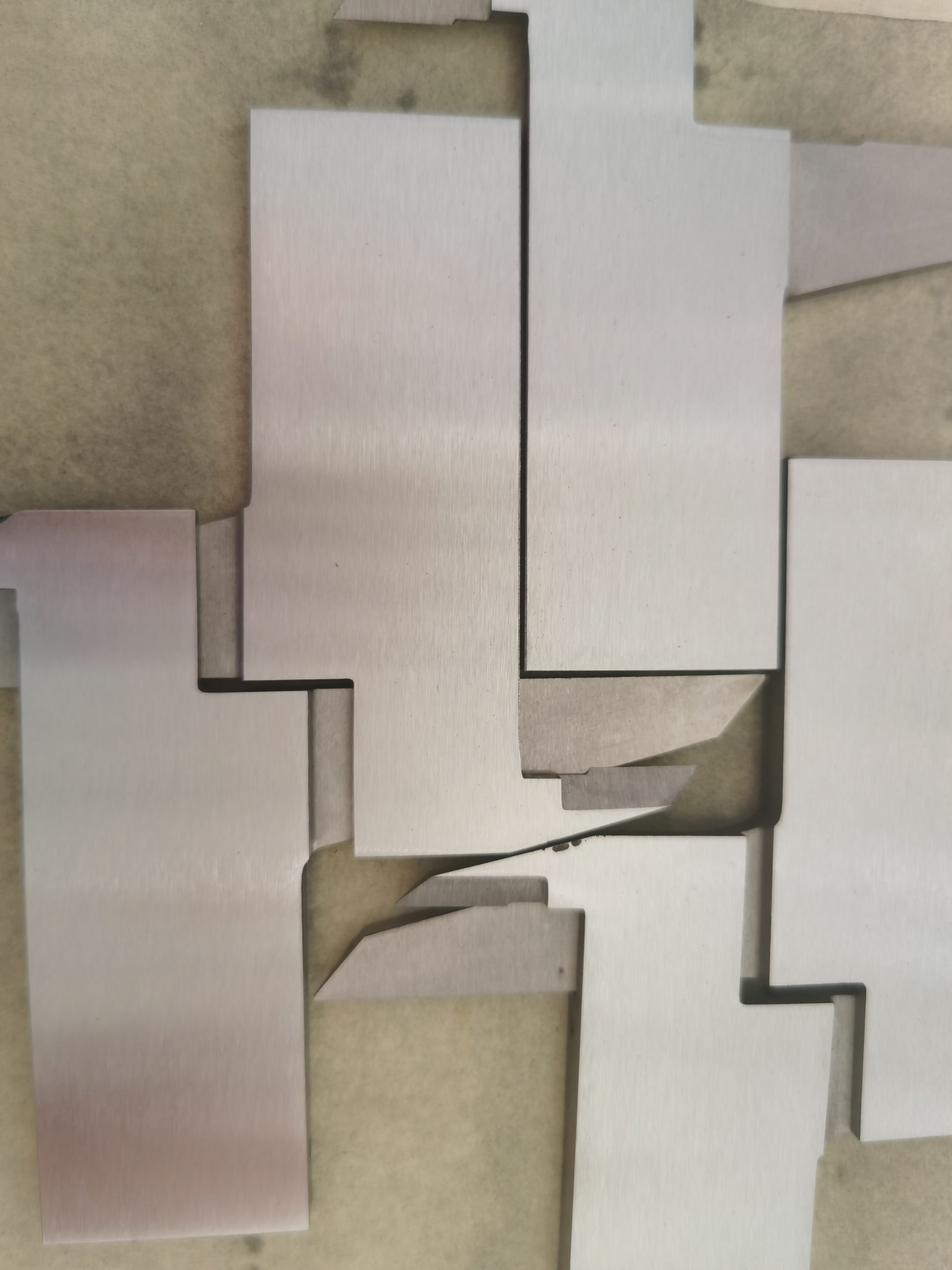

The ADV 503 mirror polishing machine uses sandpaper, and buffing wheels, designed for metal sheet grinding and polishing. It’s a perfect solution for a mirror finishing machine, which has high productivity and good finish advantages, which is suitable for laser cutting parts, hardware, small flat parts

Machine Parameters

- Main motor power: 3 KW*1

- Feeding motor power:0.55KW*1

- Swing motor power: 0.25KW*1

- Voltage and frequency: 380V/50HZ or customized

- Spindle speed:1430r/min

- Feeding speed:3.5m/min (Frequency control speed)

- Swing frequency:72times/min (Frequency control speed)

- Work table height:750mm

- Available roughness: ≤0.2µm(Through surface friction many times)

- Polishing efficiency:0-3 minutes per piece

- Size of machine:1300*800*1350mm(L*W*H)

More Info

Features of ADV 503 flat sheet mirror polishing machine

- This machine is mainly used for grinding and polishing metal plates and flat parts, using sandpaper and buffing wheels for the best finish.

- The worktable feed speed and swing frequency are adjustable

- The worktable performs reciprocating motion, and the reciprocation number can be set according to the polishing effect.

- The reciprocating stroke of the worktable can be adjusted

- The installation, operation, and maintenance are simple and convenient, move-aided time is short, and low labor intensity

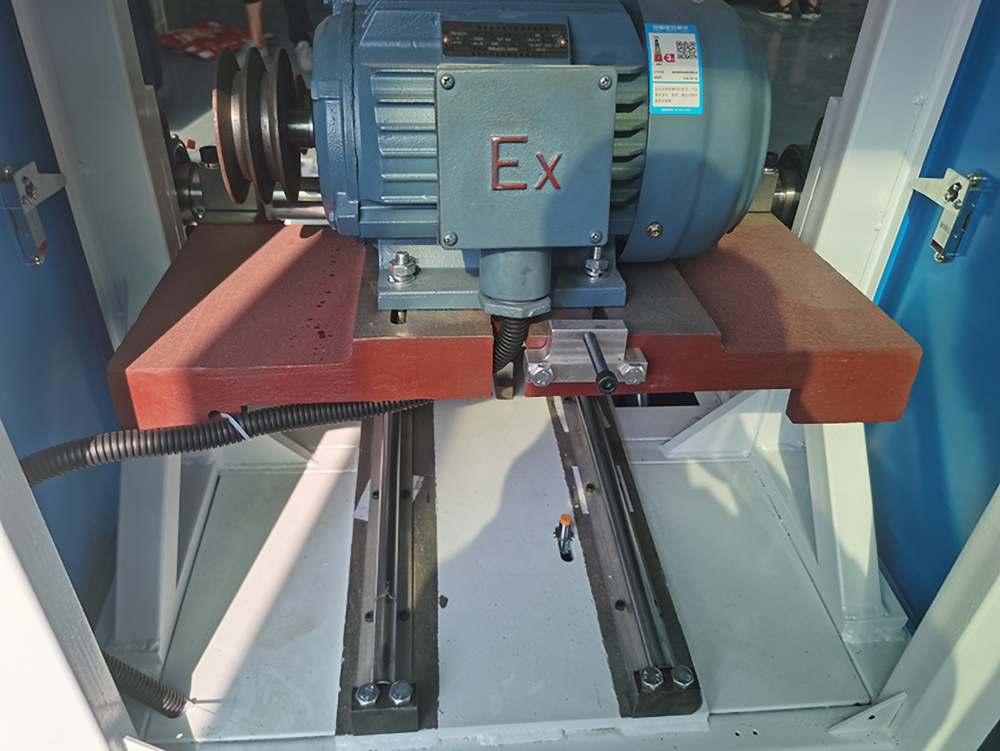

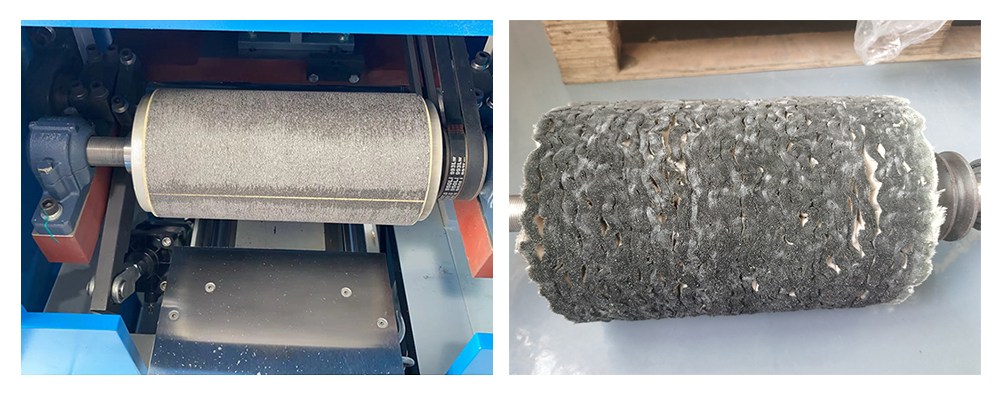

Main engine

Equipped with an electric motor to drive the spindle. The spindle can use the sandpaper or buffing wheel, but it can’t be used at the same time.

The spindle uses tape to fix the sandpaper. When using the buffing wheel, you need to replace the new spindle

Sturdy frame

Mass produced machine frame, available for delivery within 7 days

Lifting system

This system mainly use for different thickness of workpiece. Thickness can be 1-80mm

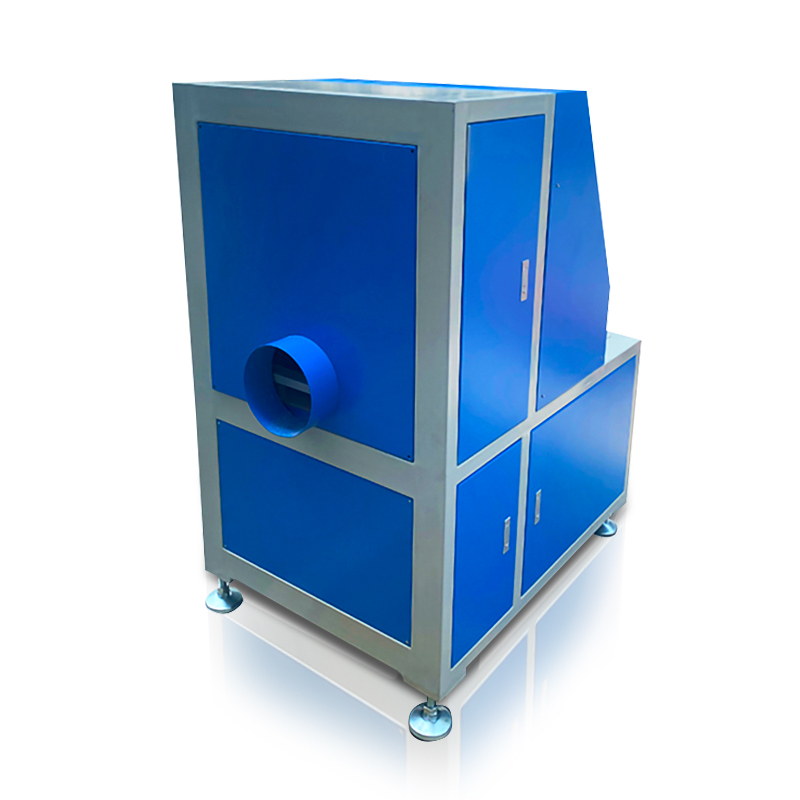

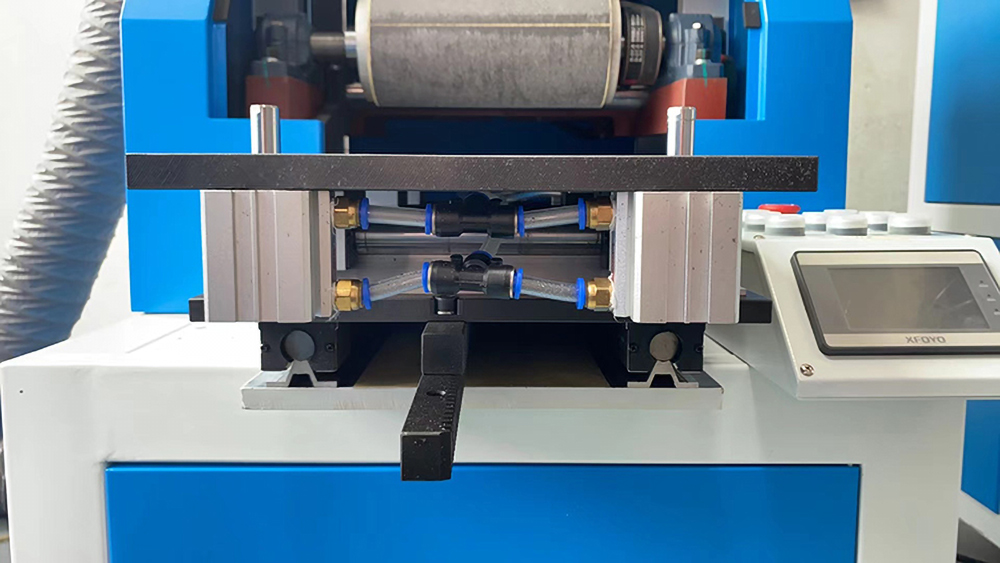

Pneumatic system

This system provides source for the air cylinder and controls the movement

Sandpaper spindle

Sandpaper of different grits can be replaced to grind and remove the oxide layer and rust of the metal parts

Buffing wheel spindle

Different wheels can be changed to achieve a brushed finish and mirror polish