Ébavurage de tôles et arrondissage des bords

Lors de l'usinage de pièces en tôle, la découpe laser et l'emboutissage sont les procédés les plus fréquemment utilisés. Ces opérations mécaniques répétitives entraînent l'apparition de bavures plus ou moins vives sur les pièces. Ces arêtes vives peuvent non seulement blesser les opérateurs lors de la manipulation et de l'installation, mais aussi corroder les pièces projetées, affectant ainsi la qualité et l'aspect du produit. Par conséquent, pour améliorer le rendement de l'usinage suivant, l'ébavurage et l'arrondi des bords sont des étapes essentielles. L'arrondi des bords permet de meuler uniquement le contour et les arêtes vives de la pièce sans endommager la surface, protégeant ainsi efficacement le revêtement. Convient aux tôles galvanisées, aux tôles d'aluminium revêtues, aux tôles de cuivre, aux tôles d'acier inoxydable et autres surfaces nécessitant une protection. L'ébavureuse entièrement automatique remplace le meulage à l'aide de limes, de grattoirs ou d'outils électriques ou pneumatiques, rendant le meulage des pièces plus uniforme, plus sûr, réduisant efficacement les coûts de main-d'œuvre et améliorant l'efficacité de la production.

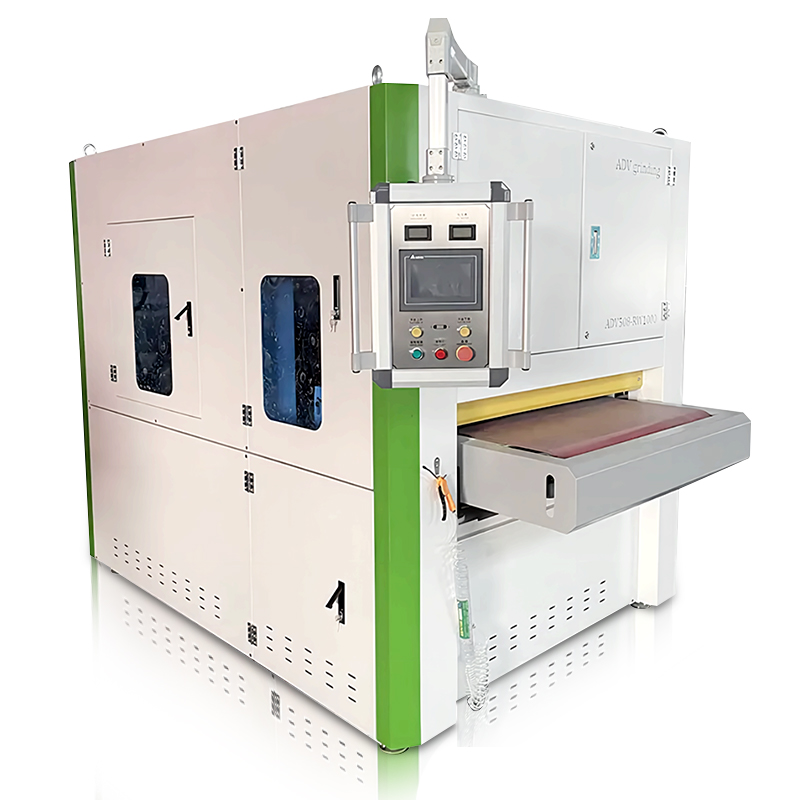

Applicable à : ADV 508-RW ADV 508-RY ADV 508-HR ADV 508-RYW

Applicable à : ADV 508-RW ADV 508-RY ADV 508-M300 ADV 508-RYW

Applicable à : ADV 508-RW ADV 508-RY ADV 508-M300 ADV 508-RYW

Applicable à : ADV 508-Rr ADV 508-RW ADV 508-RY ADV 508-M300 ADV 508-RYW

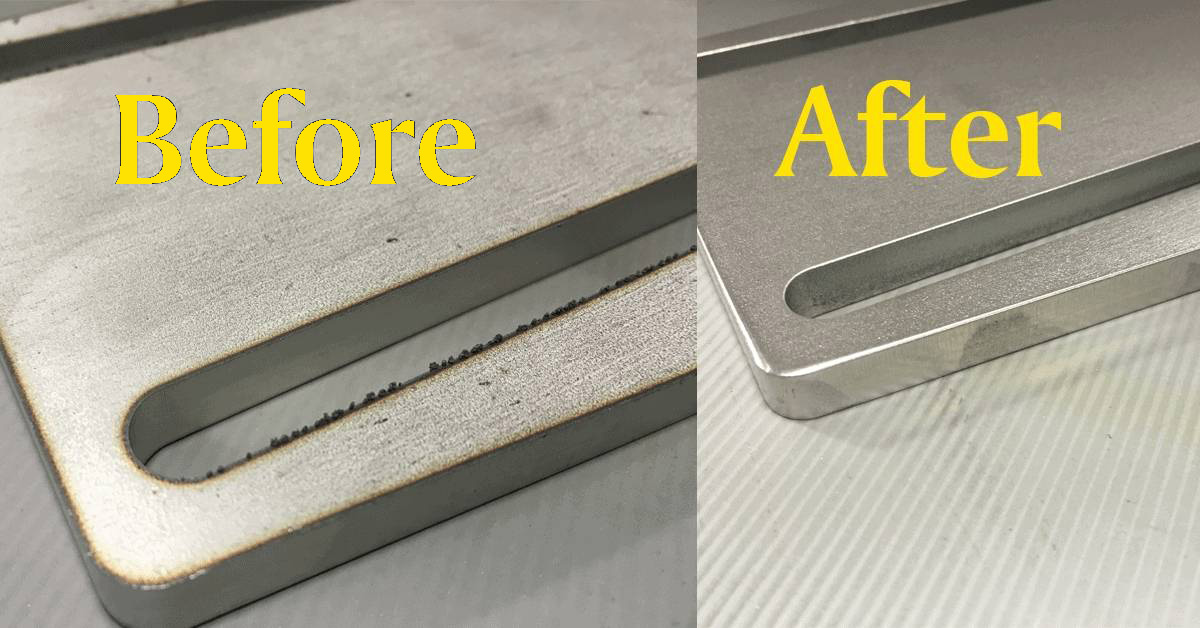

Comparaison des effets

ADV 508-Rr

La machine de finition de la série ADV 508-Rr peut traiter divers motifs, notamment le fil court n° 4 et le fil droit long et fin à des fins décoratives.

ADV 508-RY

ADV 508-RY convient à l'élimination de la couche d'oxyde métallique et à l'effet de lignes aléatoires uniformes de surface

ADV 508-RW

ADV 508-RW convient à l'acier inoxydable, aux plaques d'aluminium, aux plaques froides, à l'acier au carbone, aux pièces revêtues, aux plaques galvanisées

ADV 508-M300

ADV 508-M300 avec platine à vide ou magnétique pour l'usinage de petites pièces