ADV LG32

Descrizione del prodotto

Macchina economica per livellare e appiattire le parti metalliche più piccole

1. La nostra serie di raddrizzatori ADV LG32 fornisce lamiere e parti piatte quasi completamente prive di sollecitazioni interne, con un notevole risparmio di tempo, rendendo la vostra produzione più efficiente.

2. La disposizione è inoltre molto stretta, un gran numero di rulli di supporto sfalsati assicurano che il rullo livellatore non si pieghi e non si deformi quando viene sollecitato.

3. Risultati di livellamento costantemente eccellenti, soprattutto con lamiere e parti metalliche sottili.

4. Progettato specificamente per materiali sottili: spessori di materiale da 0,4 mm a 2,4 mm (da 0,015″ a 0,1″)

Parametri della macchina

|

No

|

Modello

|

ADV LG32-300

|

ADV LG32-500

|

ADV LG32-800

|

ADV LG32-1300 |

|

1

|

Diametro del rullo

|

32mm

|

|||

|

2

|

Numero del rullo

|

19

|

|||

|

3

|

Larghezza nominale livellata

|

300mm

|

500mm

|

800mm

|

1300mm |

|

4

|

Spessore nominale della piastra

|

0,4-1,2 mm

|

0,4-1,2 mm

|

0,4-1,2 mm

|

0,4-1,2 mm |

|

5

|

Spessore massimo della piastra

|

2,4 mm

|

|||

|

6

|

Precisione livellata

|

Ciao/Buongiorno

|

|||

|

7

|

Applicabile

|

Avvolgimento di nastri, strisce di acciaio, lamiere, ecc.

|

|||

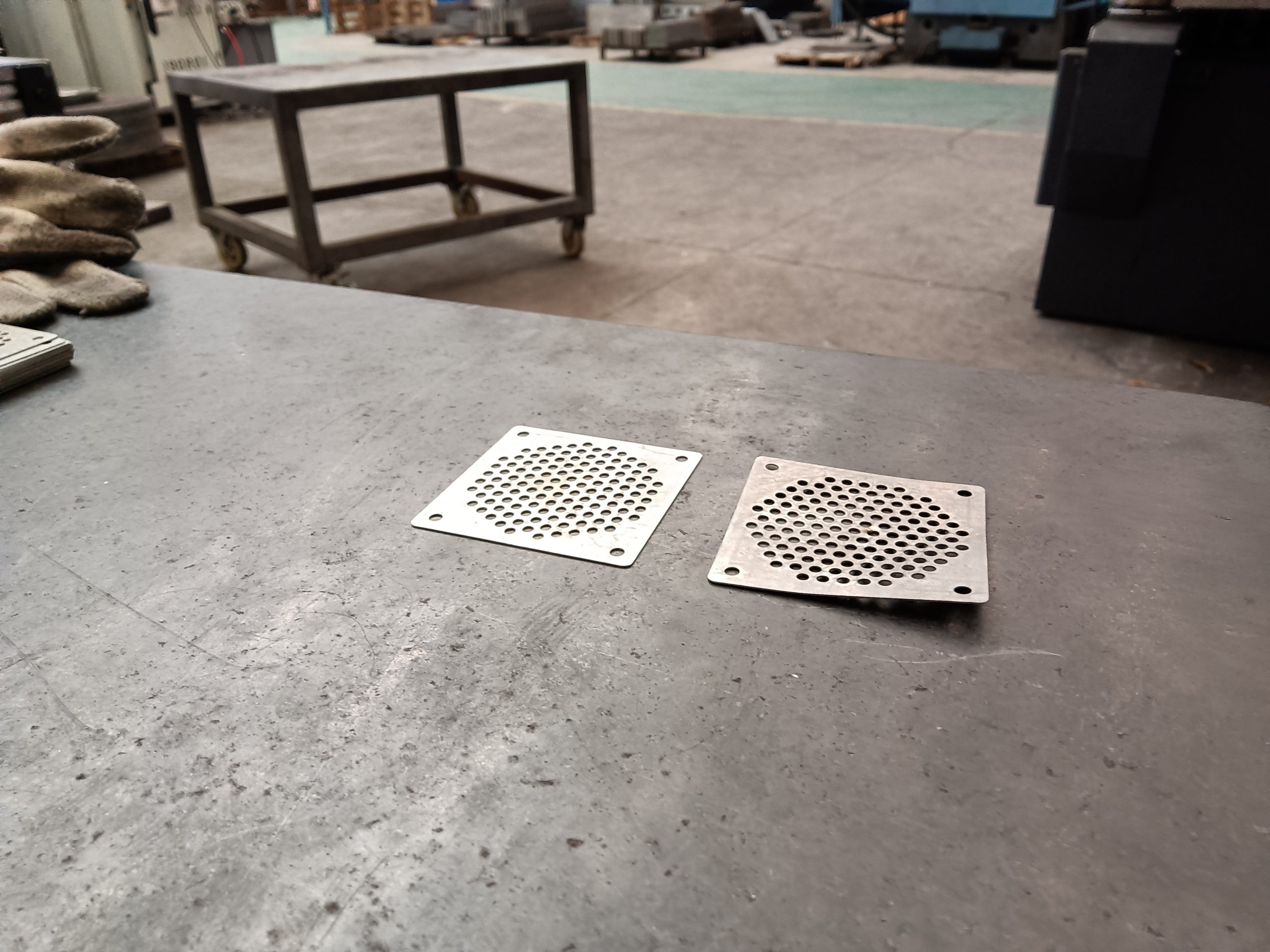

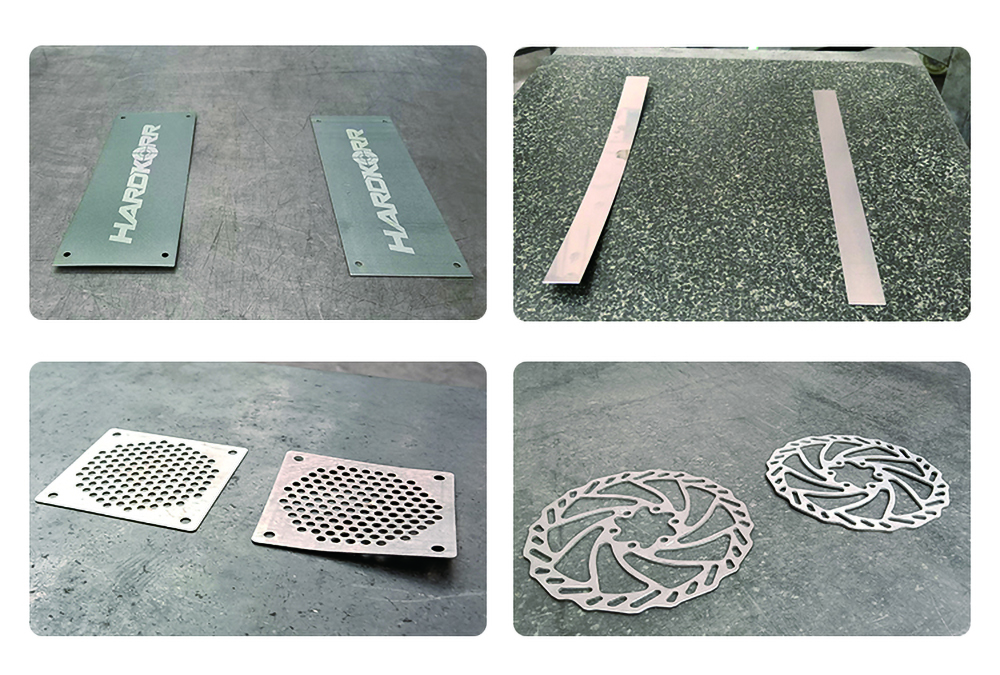

Industria di applicazione e campione

Per saperne di più

Caratteristiche della macchina livellatrice per parti meccaniche di precisione

È utilizzato da centinaia di clienti. Tutto ciò lo rende il livellatore di metallo numero 1 per parti sottili.

1 Ci sono un gran numero di rulli di livellamento e sono disposti in modo ravvicinato: serie 32/40/63/80 19 rulli; serie 100 17 rulli; serie 125 15 rulli; serie 160 13 rulli; serie 200 11 rulli

2 Il diametro del rullo di raddrizzatura è ovviamente 50% più piccolo di quello della macchina di raddrizzatura meccanica a rulli paralleli, e la disposizione è anche molto stretta. Un gran numero di rulli sfalsati

3 La disposizione è inoltre molto stretta, un gran numero di rulli di supporto sfalsati assicurano che il rullo livellatore non si pieghi e non si deformi quando è sottoposto a sollecitazioni.

4 La forte pressione idraulica mantiene sempre invariata la distanza (limite morto meccanico) tra i rulli superiore e inferiore.

5 La struttura della pressa idraulica a tre travi con buona rigidità riduce al minimo il grado di deformazione complessiva della macchina durante il funzionamento.

6 Lo spazio sul lato destro dell'attrezzatura è aperto per facilitare la pulizia, la manutenzione e la sostituzione del rullo livellatore

7 Nuove apparecchiature per la lavorazione della plastica a basso consumo energetico, rispettose dell'ambiente e a basse emissioni di carbonio per piastre metalliche e parti di aerei