ADV LG100/125/160

Video del prodotto

Descrizione del prodotto

Macchina livellatrice per piastre pesanti ADV LG100/125/160

Le serie G100/ G125/ G160 possono gestire vari tipi di lamiere medie e spesse e lamiere laminate a caldo, tra cui acciaio al carbonio, acciaio inossidabile, acciaio legato, ecc.

Poiché queste piastre sono solitamente di grandi dimensioni e peso, la struttura della nostra macchina livellatrice è molto resistente e robusta.

Anche quando si lavorano lamiere più spesse, la macchina livellatrice della serie G può comunque eseguire più livellamenti della lamiera tramite la pressione alternata di più rulli di livellamento di grande diametro, mantenendo comunque un effetto di livellamento ad alta precisione, garantendo la planarità della lamiera e minori sollecitazioni residue.

Parametri della macchina

| No | Modello | ADV LG125-500 | ADV LG125-1100 | ADV LG125-1600 | ADV LG125-2100 | ADV LG125-2600 |

| 1 | Diametro del rullo | 125 | ||||

| 2 | Numero del rullo | 15 | ||||

| 3 | Larghezza nominale livellata | 500mm | 1100mm | 1600mm | 2100mm | 2600mm |

| 4 | Spessore nominale della piastra | 5-12mm | 5-12mm | 5-12mm | 5-12mm | 5-12mm |

| 5 | Spessore massimo della piastra | 30mm | ||||

| 6 | Precisione livellata | E | ||||

| 7 | Applicabile | acciaio a strisce, lamiera spessa, lamiera laminata a caldo | ||||

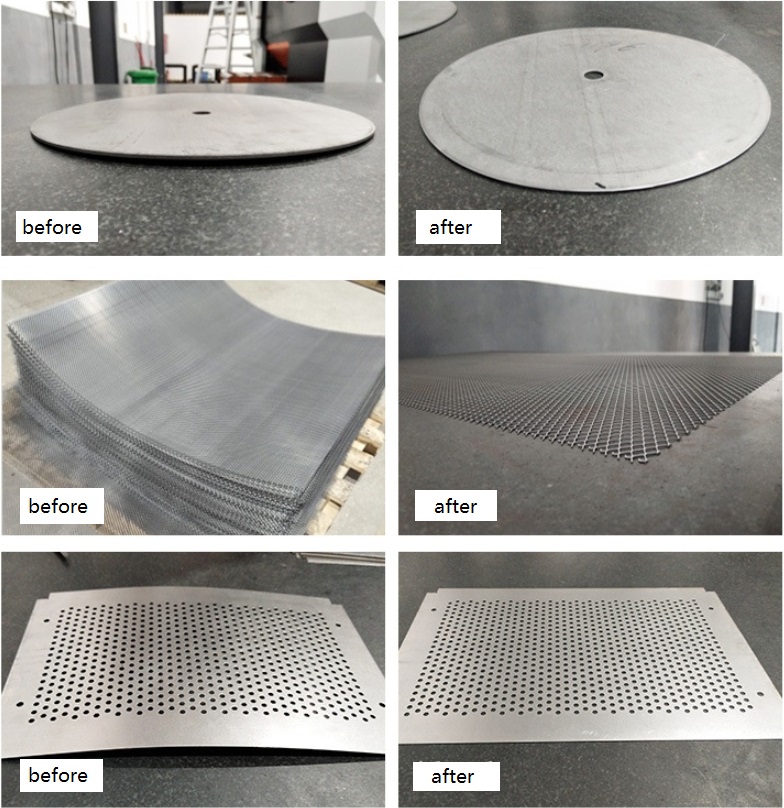

Industria di applicazione e campione

Per saperne di più

1 Esistono numerosi rulli di livellamento, disposti in modo ravvicinato: serie 32/40/50/63/80 con 19 rulli; serie 100 con 17 rulli; serie 125 con 15 rulli; serie 160 con 13 rulli. ecc.

2 Il diametro del rullo raddrizzatore è ovviamente 50% più piccolo di quello del rullo raddrizzatore parallelo meccanico

macchina, e la disposizione è anche molto stretta. Un gran numero di sfalsati

3 La disposizione è inoltre molto stretta, un gran numero di rulli di supporto sfalsati assicurano che il rullo livellatore non si pieghi e non si deformi quando è sottoposto a sollecitazioni.

4 La forte pressione idraulica mantiene sempre invariata la distanza (limite morto meccanico) tra i rulli superiore e inferiore.

5 La struttura della pressa idraulica a tre travi con buona rigidità riduce al minimo il grado di deformazione complessiva della macchina durante il funzionamento.

6 Lo spazio sul lato destro dell'attrezzatura è aperto per facilitare la pulizia, la manutenzione e la sostituzione del rullo livellatore

7 Nuove apparecchiature per la lavorazione della plastica a basso consumo energetico, rispettose dell'ambiente e a basse emissioni di carbonio per piastre metalliche e parti di aerei