Sheet metal deburring and edge rounding

When processing metal sheet metal parts, laser cutting and stamping are the most frequently used processes, and under these mechanical repetitive actions, more or less sharp burrs will appear on the sheet metal parts. Sharp edges will not only cause injuries to employees during handling and installation, but will also corrode the sprayed parts, thus affecting product quality and appearance. Therefore, in order to improve the yield of the next process, deburring and edge rounding are essential steps Edge rounding only grinds the contour and sharp edges of the workpiece without damaging the surface, effectively protecting the workpiece coating, and is suitable for galvanized sheets, coated aluminum sheets, copper sheets, stainless steel sheets and other surfaces that require protection The fully automatic deburring machine replaces the treatment plan of grinding with files, scrapers or electric or pneumatic tools, making the workpiece grinding more uniform, safer, and effectively reducing labor costs and improving production efficiency.

Applicable to: ADV 508-RW ADV 508-RY ADV 508-HR ADV 508-RYW

Applicable to: ADV 508-RW ADV 508-RY ADV 508-M300 ADV 508-RYW

Applicable to: ADV 508-RW ADV 508-RY ADV 508-M300 ADV 508-RYW

Applicable to: ADV 508-Rr ADV 508-RW ADV 508-RY ADV 508-M300 ADV 508-RYW

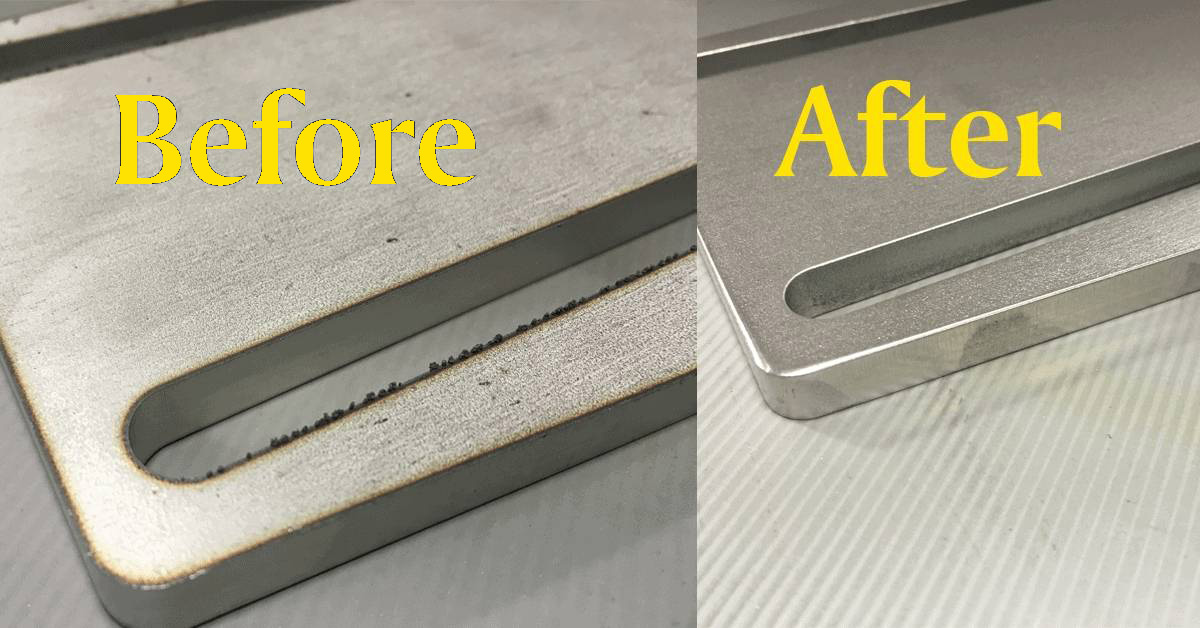

Effect comparison

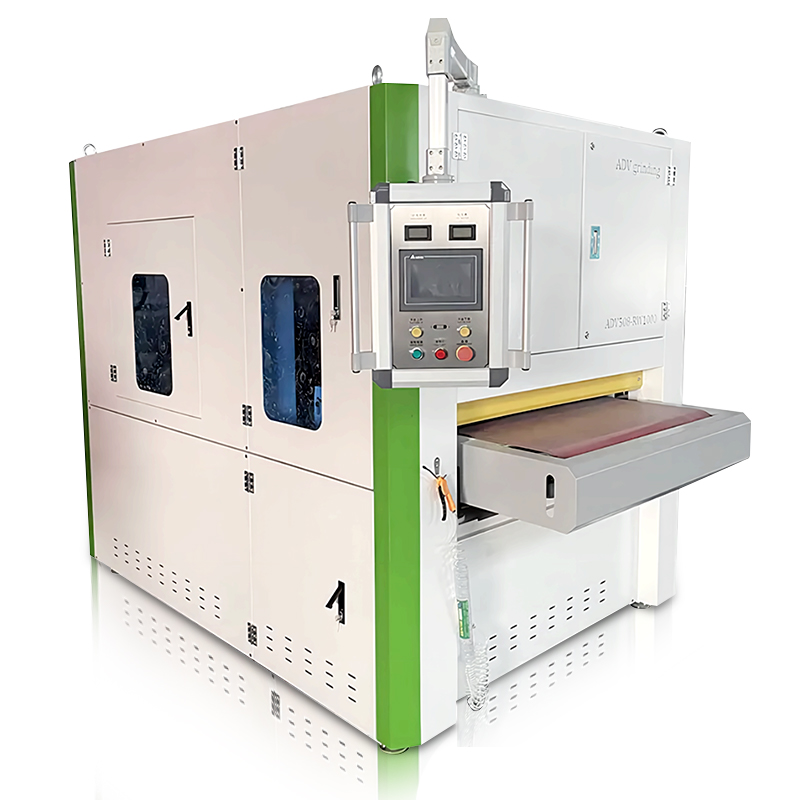

ADV 508-Rr

ADV 508-Rr series finishing machine can process various patterns, including No.4 short wire and hairline long straight wire for decorative purposes.

ADV 508-RY

ADV 508-RY is suitable for Metal removal oxide layer and surface uniform random lines effect

ADV 508-RW

ADV 508-RW is suitable for Stainless steel, aluminum plate, cold plate, carbon steel, coated workpiece, galvanized plate

ADV 508-M300

ADV 508-M300 with vacuum or magnetic stage for machining small parts