Sheet metal deburring and edge rounding

ADV provides machinery designed for the deburring and edge rounding of laser and punched parts. The selection of deburring technologies is based on the specific requirements of the final product. Factors such as geometry, quantity, and part dimensions influence the configuration of the machine. The overarching objective is to consistently attain high-quality results, ensuring effective deburring and edge rounding for both punched and laser-cut parts.

Applicable to: ADV 508-RR wide belt metal sanding machine ADV 508-M300 Swing Arm Grinding and Deburring Machine ADV 508-RW sheet metal deburring and edge rounding machine ADV 508-RY deburring and perfect finishing machine for steel parts

Applicable to: ADV 508-RR wide belt metal sanding machine ADV 508-M300 Swing Arm Grinding and Deburring Machine

Applicable to: ADV 508-M300 Swing Arm Grinding and Deburring Machine ADV 508-RW sheet metal deburring and edge rounding machine ADV 508-RY deburring and perfect finishing machine for steel parts ADV 508-RYW 3-in-1 industrial deburring edge rounding machine ADV 508-HRW 3-in-1 heavy slag removal edge breaking and rounding machine

Applicable to: ADV 508-RR wide belt metal sanding machine ADV 508-Rr no.4/hairline sheet metal finishing machine ADV 508-RRr stainless steel sheet hairline polishing machine ADV 508-Sheet To Sheet Grinding & Polishing Line

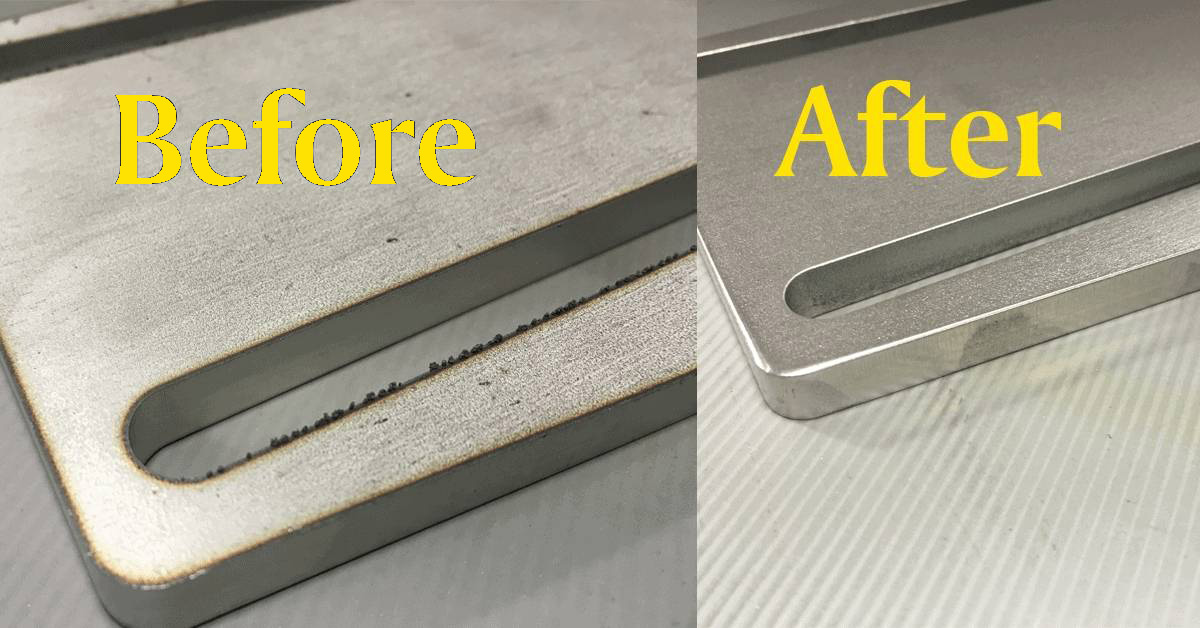

Effect comparison

ADV 508-M300 Swing Arm Grinding and Deburring Machine

ADV 508-M300 with vacuum or magnetic stage for machining small parts

ADV 508-RR wide belt metal sanding machine

ADV 508-RR series is used for metal surface wire drawing, oxidation skin, polishing, slight chamfering.

ADV 508-RW sheet metal deburring and edge rounding machine

ADV 508-RW series is used for deburring, edge rounding, laser oxide removal and surface uniform random lines of various sheet metal parts

ADV 508-RY deburring and perfect finishing machine for steel parts

ADV 508-RY is suitable for Metal removal oxide layer and surface uniform random lines effect