Deburring of Plasma, Oxyfuel, & Flame-Cut Parts

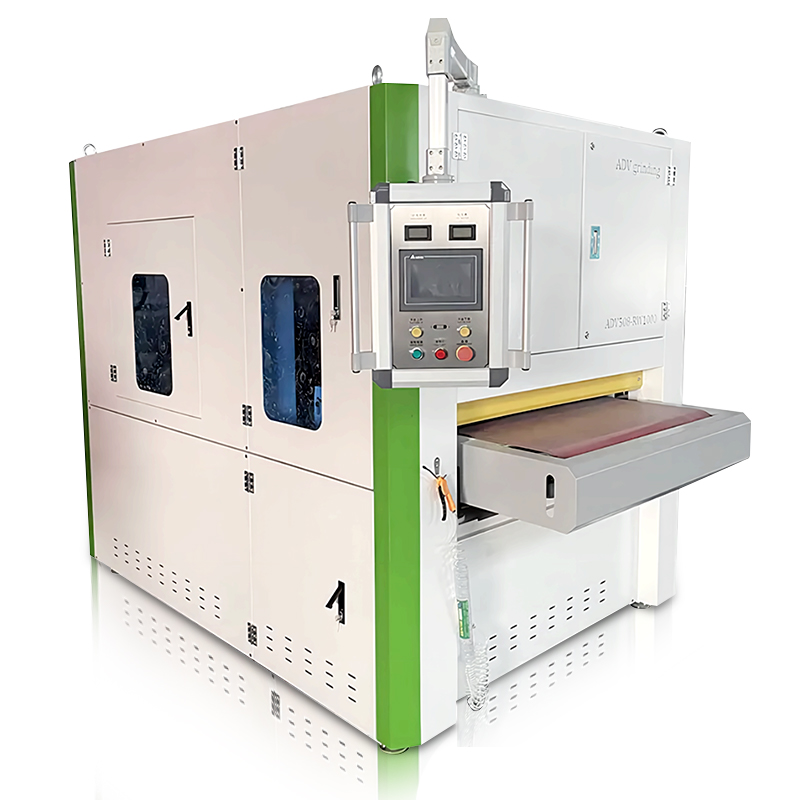

ADV-508 series is meticulously crafted for the post-processing of materials following plasma, oxyfuel, and flame cutting. This machine excels in deburring and edge rounding parts with a thickness of up to 100 mm, offering enhanced reliability compared to previous standards.

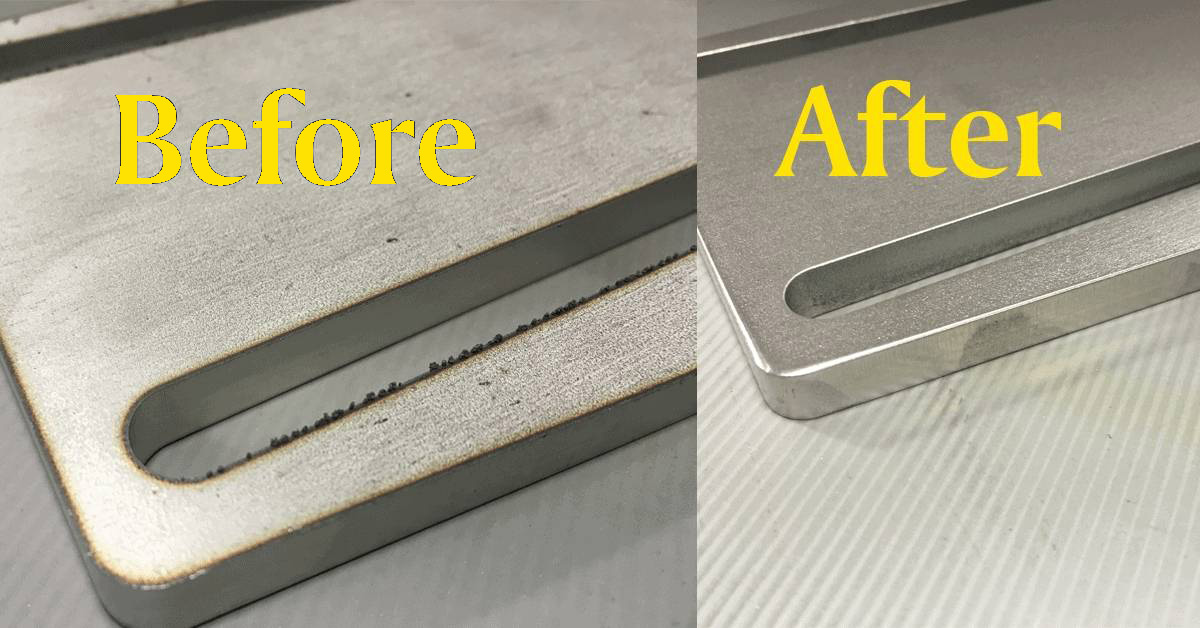

The deburring of flame-cut burrs has historically been a time-consuming process.

However, with the introduction of the ADV-508 series, this is no longer the

case. Thanks to the oscillating drum feature, this machine can efficiently and

reliably remove burrs from parts up to 100 mm thick, even when processing large

quantities.

Applicable to: ADV 508-RW ADV 508-RY ADV 508-HR ADV 508-RYW

Applicable to: ADV 508-RW ADV 508-RY ADV 508-HR ADV 508-RYW

Previously, the slag on oxyfuel or plasma-cut parts required manual removal

through hand grinding before the actual deburring process could commence. This

step was essential to guarantee a reliable and cost-effective subsequent

deburring process. Fortunately, with the machines provided by ADV, the need for

manual slag removal is now eliminated.

Applicable to: ADV 508-HR ADV 508-RY ADV 508-RW ADV 508-RYW

Applicable to: ADV 508-HR ADV 508-RY ADV 508-RW ADV 508-RYW

The edge rounding of edge for flame-cut parts includes the removal of the sharp

edge along the material. In addition, an adequate radius is conducive to paint

adhesion. With the help of the deburring blocks, the edge rounding is achieved

on both sides of the material.

Applicable to: ADV 508-Rr ADV 508-RW ADV 508-RY ADV 508-M300 ADV 508-RYW

Applicable to: ADV 508-Rr ADV 508-RW ADV 508-RY ADV 508-M300 ADV 508-RYW

効果比較

お問い合わせを送信

FAQ-米国について

はい、潜在的な顧客が当社の機械の品質や性能を評価できるよう、無料サンプルやデモンストレーションを提供しています。

を提供いたします。

ADV-Polishは、バリ取り機、金属研磨機、メタルレベリングマシンを含む金属加工ソリューションの提供を専門としています。

金属研磨機、メタルポリッシングマシン、メタルレベリングマシンなどの金属加工ソリューションを提供しています。

中国安徽省合肥市]を拠点とし、現地サポートサービスを提供しています。

現地サポートサービスを提供しています。

25年にわたる業界経験、技術革新へのコミットメント、そして卓越した製品品質。

品質により、金属加工ソリューションのトップチョイスとなっています。

FAQ-製品について

A: はい、私達にセリウムが、提供しますワンストップ サービスをあります。最初に私達は示し、郵送物の後で私達は通関手続きのためのセリウム/パッキングリスト/商業送り状の販売契約を与える。

A:お客様の製品情報と研磨工程をお聞かせください。

A: 2年間の品質保証。生涯テクニカルサポートと消耗品を最低価格で。

A: はい、ビデオや電子メールによるアフターサービスの経験が豊富です。一方、エンジニアは海外でのサービスも可能です。現地でのサービスやサンプルテストをご希望の場合は、各国に代理店もあります。