Metal Industrial Processing

- Home

- Metal Industrial Processing

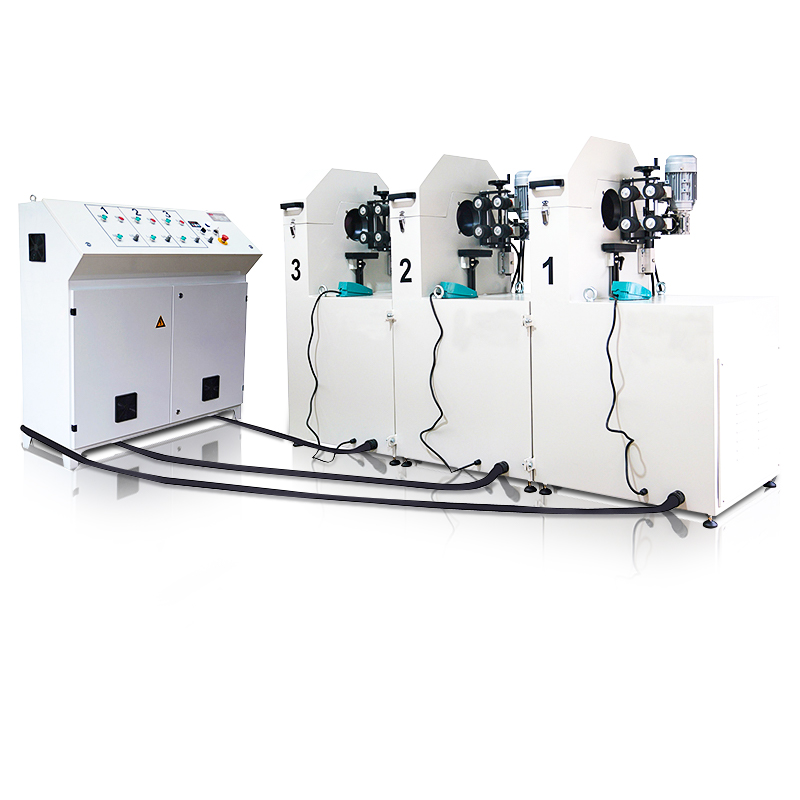

- Foundry and Forging: During the casting and forging processes, metal parts often have burrs, sharp edges, or irregular edges. Deburring machines are used to remove these defects, ensuring the flatness and quality of the parts.

- Machining: Machining processes such as milling, turning, and drilling can leave sharp edges and burrs on metal parts. Deburring machines are employed to eliminate these sharp edges, improving the quality and safety of the parts.

- Stamping Processes: Metal stamping processes often produce burrs. Deburring machines are used to remove these burrs, ensuring the flatness and quality of the final parts.

- Welding Processes: After welding, welded joints may have burrs and irregular edges. Deburring machines are used to remove these imperfections, ensuring the quality of the welding connections.

- Metal Assemblies: During assembly, metal parts may have burrs and sharp edges that interact with each other. Deburring machines are used to process these components, ensuring the smoothness and quality of the assembly.

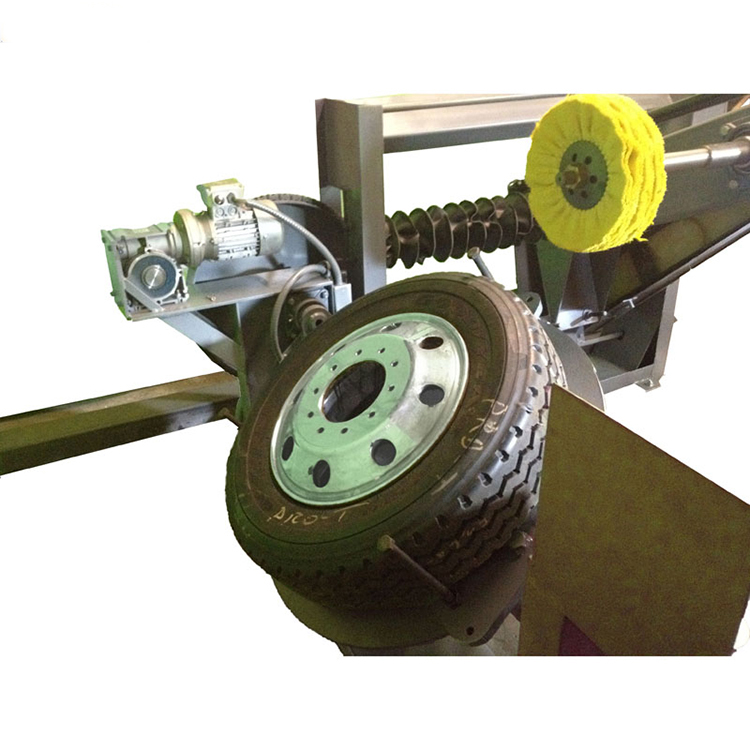

- Surface Treatment: Metal polishing machines are used to improve the smoothness and appearance of metal surfaces. This is crucial in high-end manufacturing, aerospace, medical device manufacturing, and other fields.