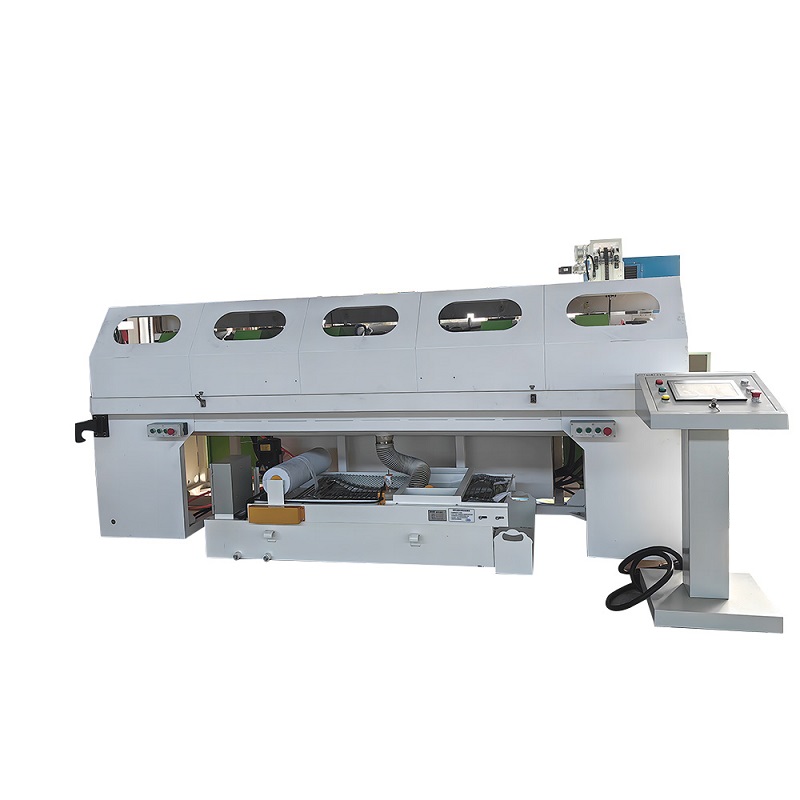

ADV 108-H6 automatic tube polishing machine

Vídeo do produto

Descrição do produto

ADV 108-H6 Automatic tube polishing machine:

The machine is mainly used for grinding and polishing the outer surface oxide layer of pipes with an outer diameter of φ6-90mm. Sanding belts with different grits can be used for grinding according to the processing purpose. It has the characteristics of high production efficiency, less auxiliary time, simple operation, safety and environmental friendliness.

The whole is equipped with two sets of conveying clamping wheels for pipes with diameters of 6-30mm and 30-90mm, which are easy to disassemble and use. The machine needs to add an adjustable bushing at the discharge point to prevent the vibration caused by the rotation of the sanding belt when conveying small pipes.

1. Automatic loading and unloading device

The mechanism consists of a material stand, a material claw assembly, a connecting rod, a cylinder, and a bearing to ensure that the workpiece can be transported to the polishing area in an orderly manner, and the polished workpiece can be transported to the same position

2. Feeding and unloading roller conveyor

The main function of this mechanism is to support and drive the workpiece to move axially for polishing. In order to drive the workpiece to rotate smoothly and synchronously, two sets of drive motors are installed on both sides of the loading and unloading for synchronous driving. The speed of the roller is variable frequency speed regulation to ensure the normal and stable polishing of the workpiece.

3. Cooling and filtering circulation system

The cooling and filtering circulation system consists of a filter, a paper belt filter, a water pipe, a coolant reflux and a coolant spraying device. It can prevent the pipe from overheating and deformation, and improve the efficiency and quality of polishing, especially for thin pipes

4. Air knife

After the main machine is polished, add a set of air knife devices for pipe drying

5. Polishing main machine

The machine has 6 sets (1 set of two sanding belts) of grinding heads. The function of the grinding head is to support the sanding belt and drive the sanding belt to rotate at high speed to polish the workpiece.

Parâmetros da máquina

Item:

Available tube diameter: 6–90 mm

Available tube thickness: 0.33-2 mm

Available tube weight: ≤ 60kG

Abrasive belt motor power: 2.2*6 kW

Transfer wheel motor power: 1.5*6 kW

Water Pump: 1.5 kW

Speed of abrasive belt: 7.8-18 m/s

Speed of feeding: 0.7-4 m/min

Surface roughness Ra ≤ 0.8

Mais informações

Polishing process:

1. Install the corresponding abrasive belt according to the process requirements.

2. Arrange the workpieces to be processed neatly on the loading platform, and place the workpieces on the loading roller group through the loading claw.

3. Adjust the blocking position of the stopper synchronous adjustment mechanism to ensure that the loading claw only loads one piece at a time.

4. For workpieces of different specifications, adjust the position of the roller by starting the passive roller synchronous movement adjustment mechanism to keep the workpiece in the appropriate supporting position.

5. Start the roller drive motor, the active roller drives the workpiece and moves the workpiece axially to enter the grinding area for grinding.

6. After the workpiece enters the grinding area, the position sensor sends a signal to make the abrasive belt grinding head in this area rotate and revolve to contact the workpiece for grinding, and six groups of abrasive belts enter the grinding in turn.

7. After the processing is completed, the unloading claw places the workpiece on the unloading platform and slowly falls into the flexible soft collector.

Enviar consulta

SE INSCREVER

BOLETIM DE NOTÍCIAS

Clique aqui para deixar uma mensagem