ADV WS-30

Vídeo do produto

Descrição do produto

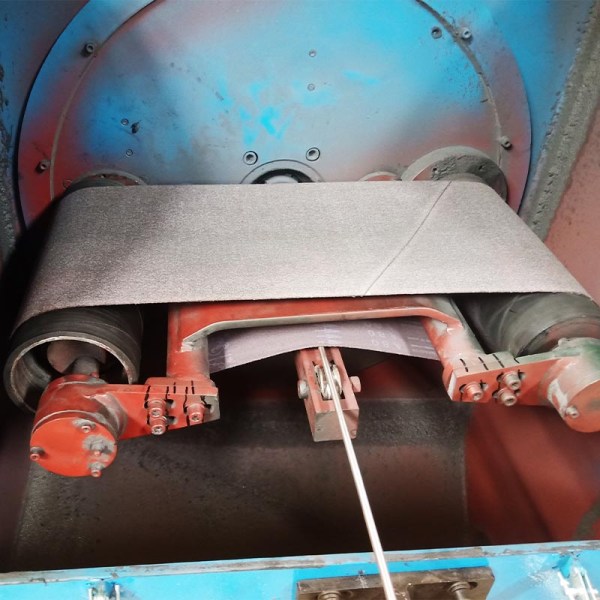

1. The sand belt polishing machine replaces pickling with an environmentally friendly and non-emission method and removes more than 98% of the oxide layer on the surface of the wire (raw material).

2. The sand belt polishing machine manufactured by ADV GRINDING uses a 7.5KW motor to rotate the turntable around the steel wire 360° to ensure that the steel wire is in contact with the abrasive belt without omission.

3. The sand belt is driven by a 7.5KW motor to move two rollers equipped with sand belts to press the surface of the wire tightly to move so that the surface of the wire is slightly cut. Generally, the surface of the wire will be evenly cut off by 0.03mm.

4. However, during work, the oxide skin is constantly stuffed between the sand grains on the surface of the sand belt, which makes the sand belt slowly fail, usually not more than 24 hours.

5. In order to improve the service life of the abrasive belt, the steel brush sheller is placed in front of the sand belt machine,

which not only ensures that the steel wire is 100% removed from the oxide layer but also increases the service life of the

abrasive belt by 5 times.

3. The sand belt is driven by a 7.5KW motor to move two rollers equipped with sand belts to press the surface of the wire tightly to move so that the surface of the wire is slightly cut. Generally, the surface of the wire will be evenly cut off by 0.03mm.

4. However, during work, the oxide skin is constantly stuffed between the sand grains on the surface of the sand belt, which makes the sand belt slowly fail, usually not more than 24 hours.

5. In order to improve the service life of the abrasive belt, the steel brush sheller is placed in front of the sand belt machine,

which not only ensures that the steel wire is 100% removed from the oxide layer but also increases the service life of the

abrasive belt by 5 times.

Parâmetros da máquina

|

Não

|

Item

|

Especificação

|

|

1

|

Modelo

|

ADV WS-30

|

|

2

|

Available diameter

|

1.0-30.0mm

|

|

3

|

Processing line speed

|

60-120 m/min

|

|

4

|

Common size

|

240*1300mm, 100*1210mm, 160*1210mm

|

|

5

|

Mesh

|

40 mesh, 60mesh, 80mesh, 100mesh, 200 mesh, 400,mesh, 600 mesh, ect.

|

|

6

|

Poder total

|

7.5 kw

|

|

7

|

Number of abrasive belts

|

4 pieces

|

Indústria de aplicação e amostra

The company recommends that the sand grain size of the abrasive belt be selected between 40 mesh and 600 mesh. The larger the mesh number, the smoother the surface of the steel wire. The 600 mesh sand grain can make the surface of the steel wire as smooth as a mirror. The steel wire can be directly plated with bright chrome or galvanized.

Inbound and outbound line positioning guide device

Belt tensioning device

Electromechanical control panel

Enviar consulta

SE INSCREVER

BOLETIM DE NOTÍCIAS

Clique aqui para deixar uma mensagem