Revving Up Shine: The Wheel Polishing Machine Advantage

Vibration polishing

Vibration polishing

The vibration motor generates high-frequency vibration, and the wheel hub, abrasive, and polishing liquid are mixed in the same container and rub against each other to achieve the polishing effect. It is only suitable for surface deburring, scratch removal, and basic polishing, and is not suitable for high-gloss mirror processing.

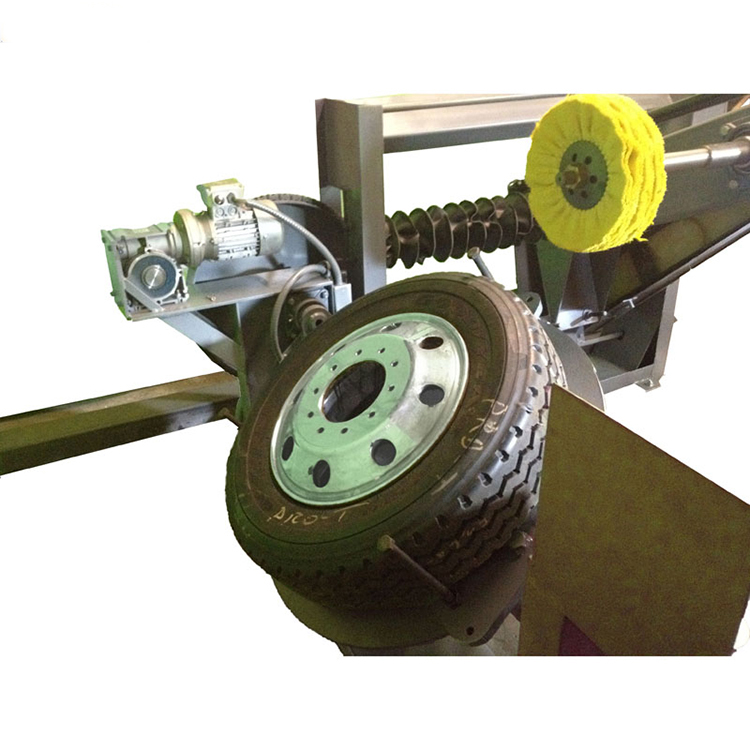

Mechanical and physical polishing

Mechanical and physical polishing

After the wheel hub is clamped, the rotating turntable and various polishing wheels interact to complete the rough grinding to high gloss polishing process in sequence. It is suitable for large-scale processing and fine polishing of specific areas to achieve high-quality mirror effects.