Why does sheet metal need to be leveled?

Leveling for medium and thick plates

Leveling for medium and thick plates

When it comes to straightening heavy or high-strength plates, we have hydraulic levelers, which are more suitable for applications that require higher straightening forces, such as large steel plates and structural parts involved in heavy industry.

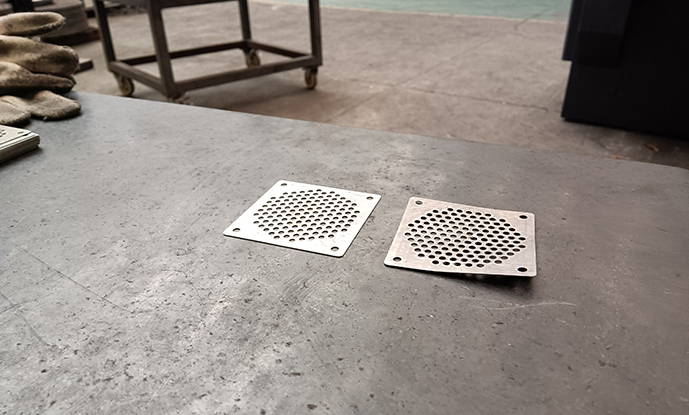

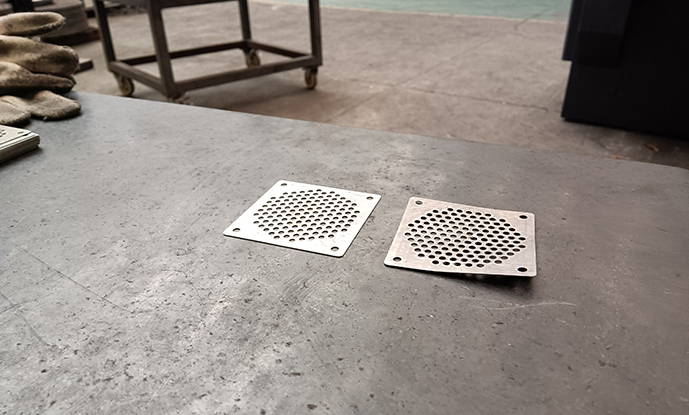

Leveling of sheet metal precision parts

Leveling of sheet metal precision parts

When straightening thin sheet metal or products with high flatness requirements, the mechanical leveling machine can quickly and accurately control the deformation of the material and remove the internal stress.