Deburring machine for Plasma and oxyfuel cut parts

ต.ค. 18 ,2023

Introduction

Cutting technologies, including laser cutting, plasma cutting, and oxyfuel cutting, have revolutionized modern manufacturing. Their precision and efficiency have made them integral in various industries. In this article, we explore the significance of these cutting methods and their wide-ranging applications.

Edge Issues and Requirements

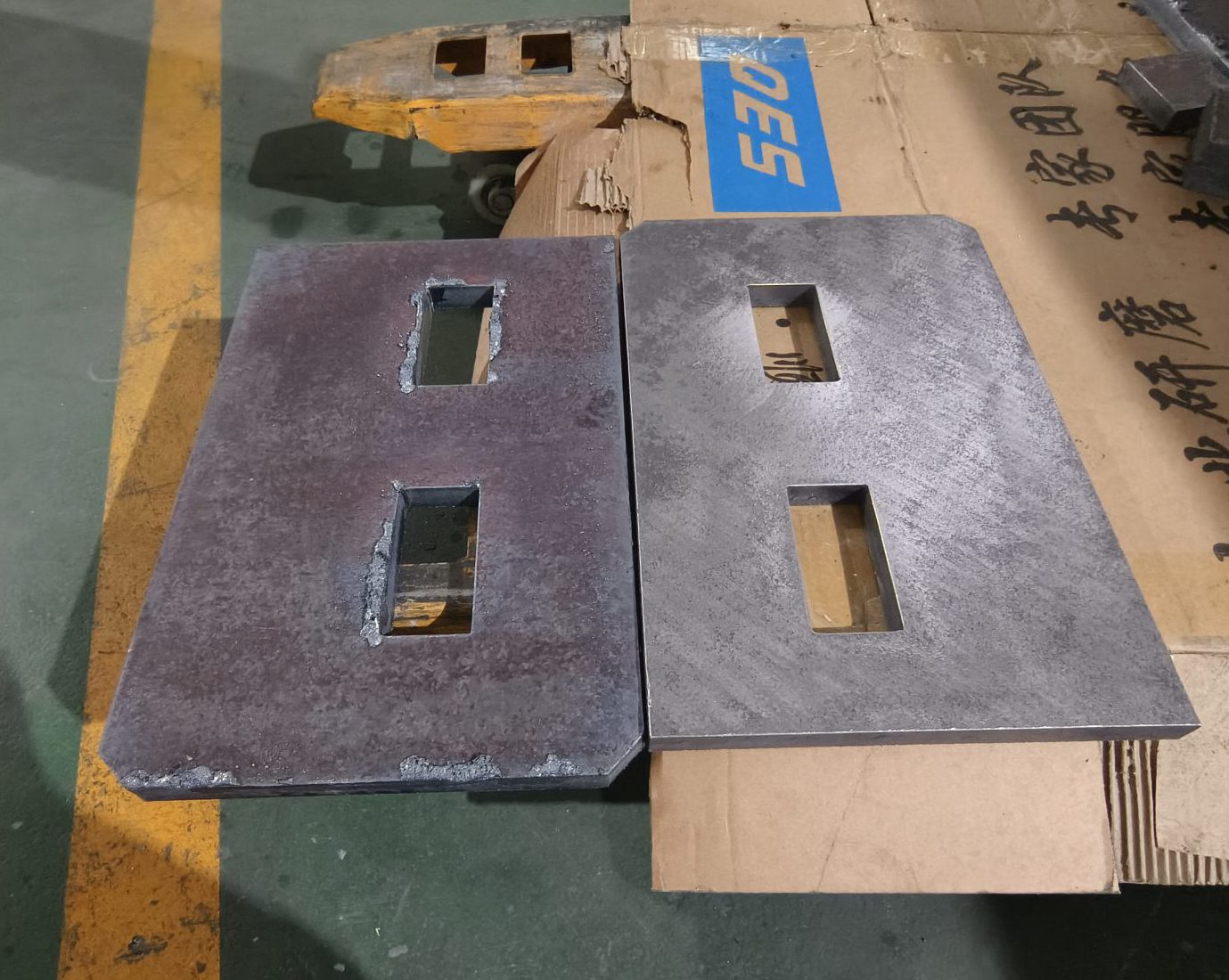

Edge Issues in Cutting

In the world of precision cutting, such as plasma and oxyfuel cutting, the pristine precision of the process can be marred by unwanted edge imperfections. These include burrs, sharp edges, and irregularities, which compromise the quality, safety, and ease of assembly of final products. Addressing these common edge issues is essential to ensure components meet industry standards and safety requirements.

High-Quality Demands

The demand for high-quality cutting is universal across diverse industries, from aerospace to construction. It goes beyond aesthetics, directly influencing a product’s performance and safety. In aerospace, precision is non-negotiable, and in construction, it’s about ensuring the safety and durability of structures. The relationship between edge quality and overall product quality is key to understanding the significance of addressing edge issues in cutting technologies.

Role of Deburring Machines

Enhancing Manufacturing Quality

Deburring machines play a crucial role in the realm of metal processing, especially in addressing edge issues. They enhance overall product quality by eliminating burrs, sharp edges, and irregularities.

Safety and Consistency

Beyond quality, deburring machines ensure safety and consistency in the manufacturing process. They remove sharp edges that could pose hazards to both operators and end-users. Consistency in edge quality is essential for maintaining safety and quality standards.

Multi-Functional Deburring Machines

Adapting to Diverse Needs

Multi-functional deburring machines represent a game-changing development in the manufacturing landscape. They have the versatility to adapt to various cutting methods and materials, making them invaluable tools in meeting the diverse requirements of different industries. This adaptability is vital in a world where no two manufacturing projects are identical, signifying a shift towards a more efficient and adaptable manufacturing process.

Customized Configurations

Deburring machines offer an incredible level of customization, allowing manufacturers to tailor the deburring process to specific project requirements. This adaptability enables the machine’s configurations to match the characteristics of the cutting methods and materials used in each project. Customization ensures that every component receives the precise deburring necessary for its unique features.

Post-Processing for Plasma Cutting

Edge Processing Challenges

After plasma cutting, post-processing becomes essential to refine edge quality. Deburring machines play a pivotal role in removing burrs and enhancing edge quality, particularly in industries like aerospace and automotive.

Edge Treatment in Oxyfuel Cutting

Challenges in Oxyfuel Cutting

Oxyfuel cutting is a common method for manufacturing metal structures and construction materials. However, it can generate burrs and sharp edges. Deburring machines address these challenges, ensuring that oxyfuel-cut components meet safety and quality requirements.

Material and Industry Differences

Material Characteristics

Different materials, from steel to aluminum and stainless steel, have unique characteristics and respond differently to various cutting methods, producing varying edge issues.

Custom Solutions

Adjusting deburring machine settings to meet customized requirements is pivotal for different industries and projects. Modern technology enables manufacturing professionals to tailor deburring solutions to address specific industry and material needs.

| Customization Aspect | Adjustable Settings |

| Abrasive Type | Grinding wheels, wire brushes, abrasive belts |

| Speed Control | Variable speed settings for different materials |

| Tool Configurations | Interchangeable tools for different deburring methods |

| Feed Rates | Adjustable feed rates for optimal results |

| Workpiece Orientation | Customizable workpiece positioning for intricate components |

This revised article provides a comprehensive overview of cutting technologies, edge issues, and the critical role of deburring machines in addressing these challenges across different materials and industries.