The Application and Selection Guide of Deburring Machines in Wall and Metal Decoration Panels

เม.ย. 21 ,2025

In the manufacturing of wall and metal decoration panels, achieving a flawless surface finish is essential. การลบคม, as a critical process, removes sharp edges and imperfections left during machining.

⇒ Contact us know more Metal Fabrication Machinery Products

What Is Deburring and Why Is It Important?

การลบคม is the process of removing small protrusions or burrs left on the surface of materials after cutting, drilling, or stamping. These imperfections can affect safety, functionality, and aesthetics, making deburring an indispensable step in producing high-quality decoration panels. Whether for metal, wood, or composite materials, deburring machines ensure smooth edges and a refined surface, thereby enhancing the overall quality of the product.

For industries focused on wall and metal decoration panels, deburring not only improves practicality but also enhances visual appeal, ensuring that products meet customer expectations and industry standards.

Application of เครื่องขัดแต่งเสี้ยน in Wall Decoration Panels

Wall decoration panels are typically made from metal, wood, or composite materials, which often leave burrs after processing. The importance of deburring in this field is as follows:

- Safety: Sharp edges on wall panels can cause injuries during handling and installation; deburring eliminates these hazards.

- Aesthetics: A smooth, burr-free surface enhances the appearance of decoration panels, making them look more professional and refined.

- ความทนทาน: Deburring helps coatings or surface treatments adhere better, extending the lifespan of the panels.

For example, a metal wall panel with burrs might disrupt a modern interior design, while a deburred panel seamlessly integrates into the decor.

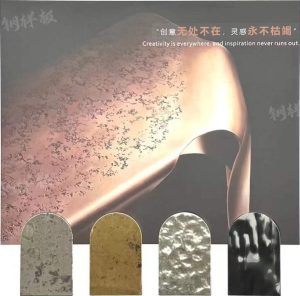

Application of Deburring Machines in Metal Decoration Panels

Metal decoration panels, such as those made from aluminum, steel, or stainless steel, require special attention during production. Deburring offers the following advantages for these materials:

- Improved Safety and Fit: Burrs on metal panels can affect assembly or cause injuries; deburring ensures precise fit and safe handling.

- Enhanced Aesthetics: A smooth, polished surface is crucial for decorative metal panels, such as architectural facades or furniture accents.

- Corrosion Resistance: Burrs can trap moisture and debris, leading to rust; deburring reduces this risk, extending the lifespan of metal panels.

For instance, in stainless steel wall cladding, deburring ensures a uniform, smooth surface that resists environmental damage while maintaining its aesthetic appeal.

วิธีการเลือกเครื่องขัดแต่งเสี้ยนให้เหมาะสม

Selecting the best deburring machine for wall and metal decoration panels involves considering several factors. Here is a practical selection guide:

1. Material Type

- Metal Panels: Belt or brush deburring machines are suitable for metals like steel or aluminum.

- Wood or Composites: Softer materials may require gentler treatments, such as sanding or light brushing.

2. Panel Size and Shape

- Large Flat Panels: Wide-belt deburring machines are ideal for handling large surfaces.

- Complex Shapes: Robotic or flexible tool equipment can handle intricate designs or tight corners.

3. Production Volume

- High Volume: Automated deburring machines save time and ensure consistency.

- Low Volume: Manual or semi-automatic equipment is more cost-effective for small batches.

4. Desired Surface Quality

- High-Gloss Finish: Use equipment with fine abrasives or polishing functions.

- Matte or Textured Effect: Coarser abrasives can achieve the desired effect.

5. Versatility

Machines that can deburr, round edges, and finish surfaces in one pass are suitable for diverse panel types.

6. Cost and Efficiency

While manual deburring is an option, investing in a machine reduces labor costs and boosts efficiency for large-scale production.

Types of Deburring Machines for Decoration Panels

The following are common types of deburring machines suitable for wall and metal decoration panels:

- Belt Deburring Machines: Use belts to smooth surfaces, ideal for large metal panels.

- Brush Deburring Machines: Rotating brushes handle flat and contoured surfaces, suitable for uniform metal finishing.

- Vibratory Deburring Machines: Gentle tumbling with abrasive media, suitable for small or delicate panels.

- Robotic Deburring Systems: High-precision automation for complex or custom panel shapes.

บทสรุป

Deburring machines play an indispensable role in the production of wall decoration panels and metal decoration panels. By removing burrs, they enhance safety, improve aesthetics, and ensure lasting quality. Choosing the right deburring machine based on material, production needs, and surface goals can significantly enhance the manufacturing process and produce high-quality decoration panels.