ADV 508-RWR

Product Video

Product Description

Save costs with our deburring machines

ADV GRINDING offers automated deburring polishing machines for laser cut, plasma cut, oxyfuel cut and punched parts. Deburr, edge round, deslag and finish your metal parts with high quality and efficiency

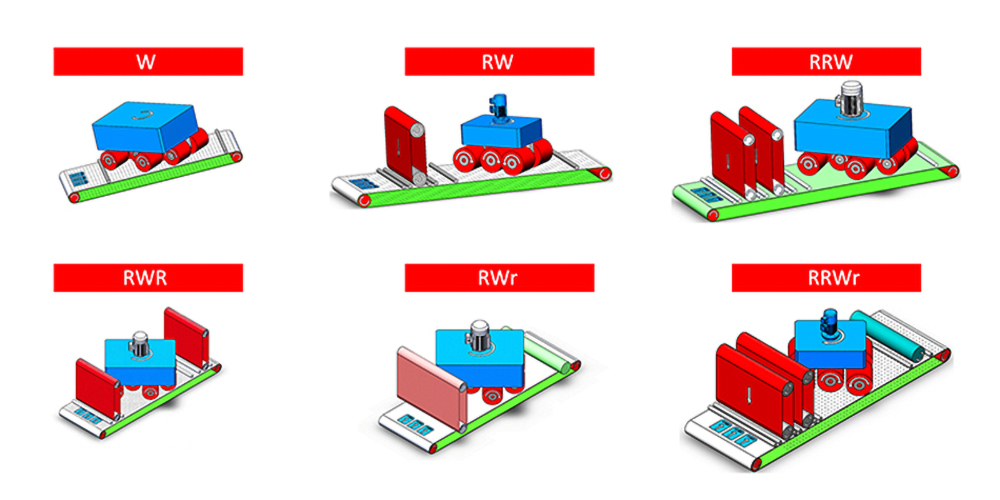

RWR series is the most popular model among the rotary brush deburring machines. This machine has a combination of a set of wide belts, a set of multiple rotating brushes, and a set of wide belts, with multiple functions such as deburring, edge rounding, finishing and laser oxide removal for different materials.

Machine Parameters

|

No

|

Item

|

Specification

|

|

1

|

Model

|

ADV 508-RWR800

|

|

2

|

Available width

|

30-800mm

|

|

3

|

Available thickness

|

0.5-100mm

|

|

4

|

Feed speed

|

1-5m/min Frequency speed

|

|

5

|

Minimum processing size | ≥30*30mm (magnet or vacuum adsorption) |

|

6

|

Main motor of abrasive belt (R) No 1 |

15 Kw |

|

7

|

Rotary brush motor power(W) No 2 | 2.2 Kw*2 |

|

8

|

Main motor of abrasive belt (R) No 3 | 15 Kw |

|

9

|

Vacuum unit motor | 15 kw |

|

10

|

Abrasive belt size | 1900*820 mm |

|

11

|

Rotary brush size | 300*300*40 mm |

| 12 | Total connecting power | 53.9 Kw |

| 13 | Machine weight | 3500 kg |

The standard available width is 630mm, 800mm, 1000mm, 1100mm, 1300mm, 1400mm, or customized.

More Info

The function of RWR series equipment

Remove silhouette edge hard burr

Remove cutting slag

Edge rounding of outside and inside profile more uniforn

Strong adsorptive force, satisfy smaller parts

Automatic compensation for abrasive material

Abrasive replacement remind

Metal removal oxide layer, surface brushed, and line grain finish

READ MORE : CONTACT ADV