Double Sided Chamfering Deburring Machine

Product Description

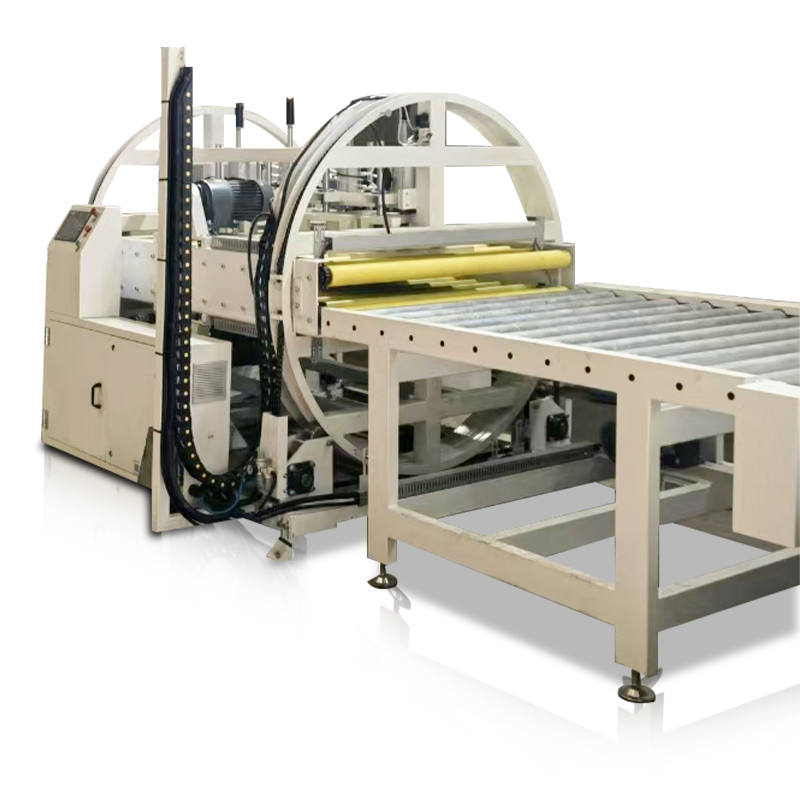

ADV 508-RR-W-F-W-1300 Series Automatic flip deburring machine

The automatic double-sided deburring machine is an automated equipment used to efficiently remove burrs from the surface of workpieces. It is mainly used in the processing fields of metals, plastics, composite materials, etc. Its core function is to improve the surface quality of workpieces, ensure processing accuracy, and optimize production efficiency. The following are its specific functions and advantages:

1. Remove burrs and improve surface quality

Source of burrs: Burrs (sharp protrusions or uneven residues) are easily generated on the edges or holes of workpieces during cutting, stamping, casting, CNC processing, etc.

Processing method: Through grinding, brushing, polishing, vibration finishing and other technologies, the burrs on both sides of the workpiece are automatically removed to make the surface smooth and flat, meeting the appearance and functional requirements of industrial products.

2. Double-sided synchronous processing

Efficiency: The front and back sides of the workpiece can be deburred at the same time, without manual flipping or secondary positioning, which significantly shortens the processing time.

Consistency: Ensure uniform double-sided processing effect to avoid errors caused by multiple operations.

3. Advantages of automated production

Manpower saving: Fully automatic operation reduces manual intervention, labor intensity and cost.

High-precision control: Precisely locate the burr position through sensors, robotic arms or CNC systems to avoid over-cutting or damage to the workpiece.

Batch processing capacity: Suitable for mass production scenarios to improve overall production line efficiency.

4. Improve product reliability and safety

Function optimization: Burrs may cause difficulty in part assembly, increased wear or electrical short circuits (such as electronic components). Removal improves product performance and service life.

Safety and compliance: Avoid sharp burrs from scratching operators or causing safety hazards to end users (such as automotive parts and medical devices).

5. Application areas

Metal processing: automotive parts, aerospace parts, precision gears, hardware, etc.

Plastic products: electronic housings, injection molded parts, connectors, etc.

6. Technical features

Adaptive control: Automatically adjust parameters (such as pressure and speed) according to the material and shape of the workpiece.

Flexible design: Compatible with workpieces of various specifications, and adapt to different needs by replacing fixtures or tools.

Quality inspection: Some high-end equipment integrates visual inspection systems to monitor the processing effect in real time.

sheet metal edge rounding

Machine Parameters

- Belt Size : 2200*1320mm(or customizable)

- Available Width : 30-1300mm

- Feed speed : 0.5-5m/min (frequency speed)

- Available Thickness : 0.5-100mm

- Belt Station Motor Power : 45.5KW

- Rotary Brush Station Power : 21 kw(sets of 6 rotary brushes) *2

- Delivery Motor Power : 1.5kw

- Vacuum adsorption motor power : 18.5 kw *2

- Machine Size(L*W*H) : 8500*2260*2300mm

Automatic flip Deburring machine parameters vary for different widths .