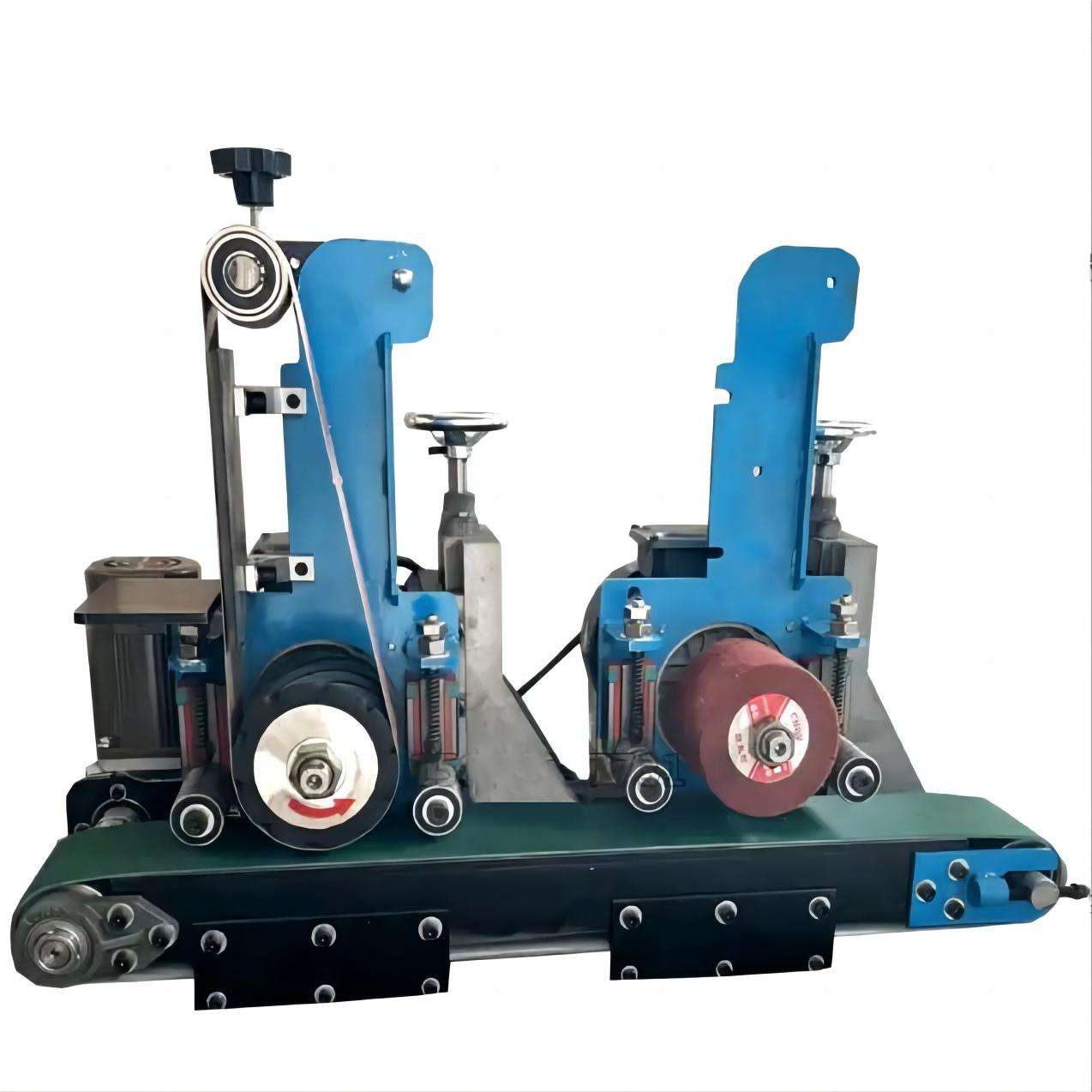

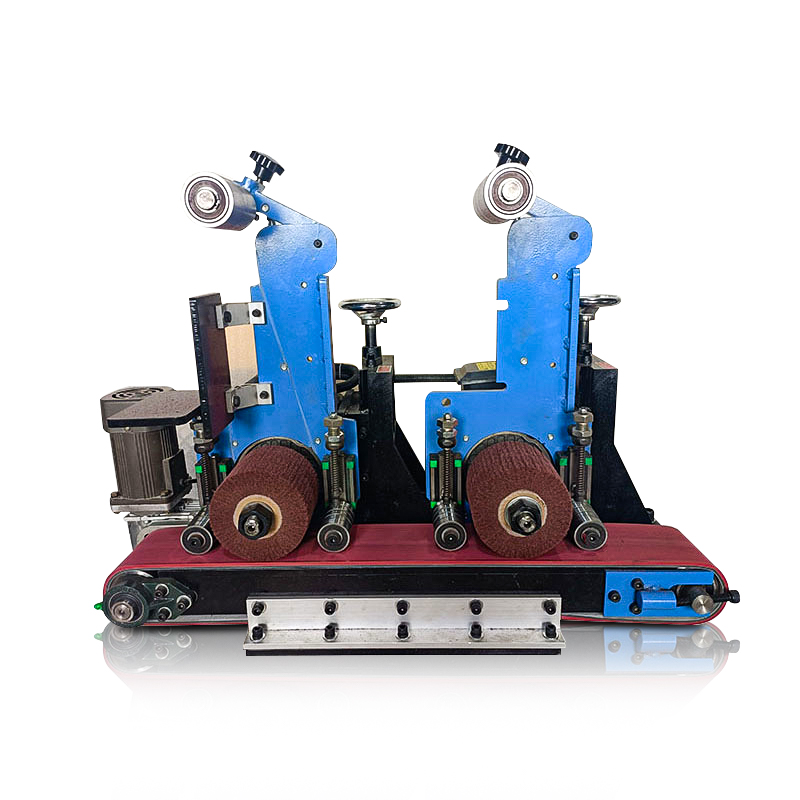

ADV 118-2

Product Video

Product Description

- For small flat metal plate material deburred, brushed and polished

- Using sand belt and scotch brite wheel to get the best finish

- The standard available width is 100mm, 150mm, or customized.

- Feeding motor, stable speed, 8m/min

- Abrasive belt speed:15m/s,adjustable speed

- The height (grinding thickness) can be adjusted up to 80mm. If the workpiece thickness exceeds 80mm, customization is supported.

- The minimum distance between the two pressure rollers is 170mm. If the workpiece is too small, it can be used with fixture or adhesive strips.

Machine Parameters

|

No

|

Item

|

Specification

|

|

1

|

Model

|

ADV 118-2

|

|

2

|

Product name

|

ADV 118-2 flat sheet polishing brushing machine

|

|

3

|

Main motor

|

2.2*2 kW

|

|

4

|

conveyor motor

|

0.18 kW

|

|

5

|

available width

|

100 mm

|

|

6

|

conveyor speed

|

8 m/min

|

|

7

|

Main motor speed

|

15m/s, adjustable speed

|

|

8

|

Belt size

|

920*100 mm

|

|

9

|

machine size

|

950*600*770 mm

|

|

10

|

Machine weight

|

187 kg

|

Application industry and sample

Application Materials: ADV 118-2 flat sheet polishing machine is suitable for stainless steel, steel, aluminum, copper, etc.

Application products: Laser-cut, waterjet-cut, punched, furniture tubes and so on.

Application Industries:

ADV 118-2 flat sheet polishing machines are widely used in the manufacture Billboard, Signs, Advertising, Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters, Sheet Metal Processing, Metals Components and Parts, Ironware, Chassis, Racks & Cabinets Processing, Metal crafts, metal art ware, elevator panel, hardware, auto parts, Glasses Frame, Electronic Parts, Nameplates, etc.

More Info

The advantages of the machine

1. The sand belt and scotch brite wheel can be used together

2. Reserved protective cover and dust suction port to protect the safety of operators, with high safety and environmental protection performance.

3. Rubber pressure wheel to protect the workpiece from damage and high temperature resistance.

4. High damping conveyor belt is resistant to high temperature, high friction resistance, and high viscosity resistance, to achieve the better grinding effect.

5. Two switch buttons to separate control of of conveyor belt and main motors, quick start-stop switch for easy operation and more safety.

6. The height of the grinding table is adjustable and can be used for workpieces of different thicknesses.

7. The machine is equipped with a frequency converter, which can be adjusted according to the thickness and size of the workpiece to control the grinding speed.

8. We promise to deliver the goods within 7 days and have a delivery guarantee.

Send Inquiry

SUBSCRIBE

NEWSLETTER

click here to leave a message