ADV LG series electric and hydraulic roller levelers

Product Description

High Precision Roller Leveler

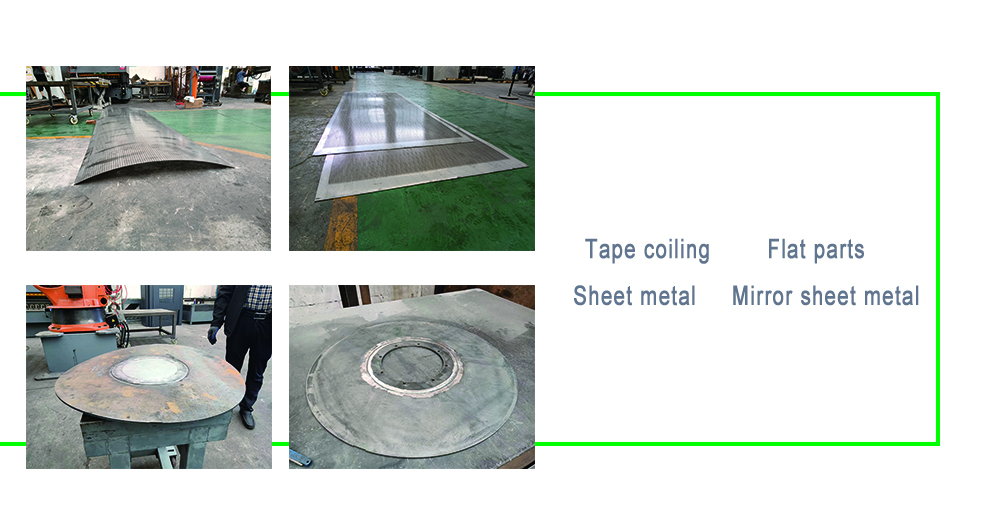

ADV machinery is committed to the research and development, production, sales and service of four-fold type / six-fold type leveling machines. Its products include mechanical precision leveling machines, hydraulic precision leveling machines, laser blanking and leveling automated production lines, stamping and leveling blanking lines, aluminum plate leveling machines, perforated mesh plate leveling machines, stamping special-shaped part leveling machines, machined product leveling machines, etc.

More Info

Leveling machines are divided into hydraulic series and mechanical series. Here is their introduction

Hydraulic precision leveling machine:

Working principle: The hydraulic leveling machine mainly provides power through the hydraulic system to drive multiple leveling rollers to move up and down, thereby repeatedly bending the metal sheet to achieve the leveling effect.

Hydraulic system: The hydraulic cylinder and hydraulic pump are used as the main power source, which can provide strong pressure and precise control.

Leveling roller: The hydraulic system controls the up and down movement of the leveling roller to achieve point-by-point leveling of the sheet.

Advantages:

High precision: The hydraulic system can provide precise control and is suitable for precision processing with higher requirements.

Powerful power: The hydraulic system provides high pressure and can handle thicker and harder metal sheets.

Disadvantages:

High cost: The hydraulic system is complex, and the manufacturing and maintenance costs are high.

Complex maintenance: The hydraulic system requires regular maintenance, including replacement of hydraulic oil and cleaning of the system.

Mechanical leveling machine:

Working principle: The mechanical leveling machine mainly provides power through the mechanical transmission system to drive the leveling roller to level the metal sheet.

Mechanical transmission: The motor, gear, connecting rod and other mechanical components are used as the power transmission system to drive the leveling roller to move.

Leveling roller: The mechanical transmission system controls the up and down movement of the leveling roller to achieve point-by-point leveling of the plate.

Advantages:

Simple structure: Compared with the hydraulic system, the structure of the mechanical system is relatively simple, and the manufacturing and maintenance costs are low.

Easy maintenance: The mechanical system maintenance is relatively simple, and the hydraulic oil does not need to be replaced as frequently as the hydraulic system.

Disadvantages:

Low precision: The control accuracy of the mechanical transmission system is relatively low, which is suitable for occasions where the flatness requirement is not high.

Limited power: The power provided by the mechanical system is relatively small, which is not suitable for processing thicker and harder metal sheets.

Read More : Sheet Metal Leveling Machine >>>