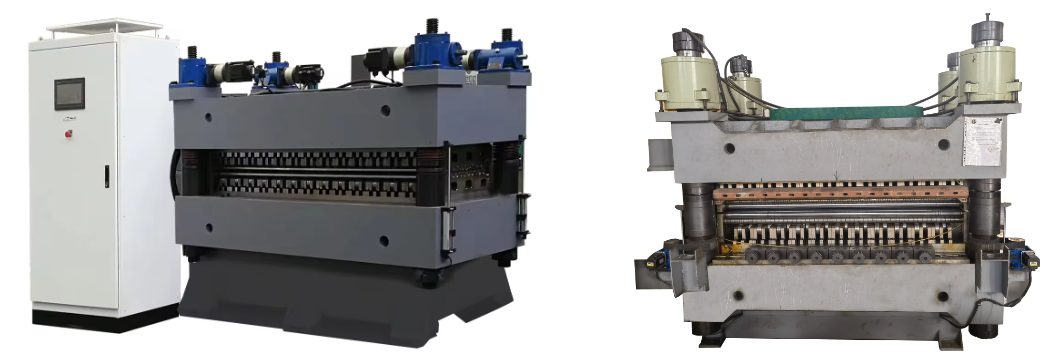

ADV-LG40 series CNC leveler

Product Video

Product Description

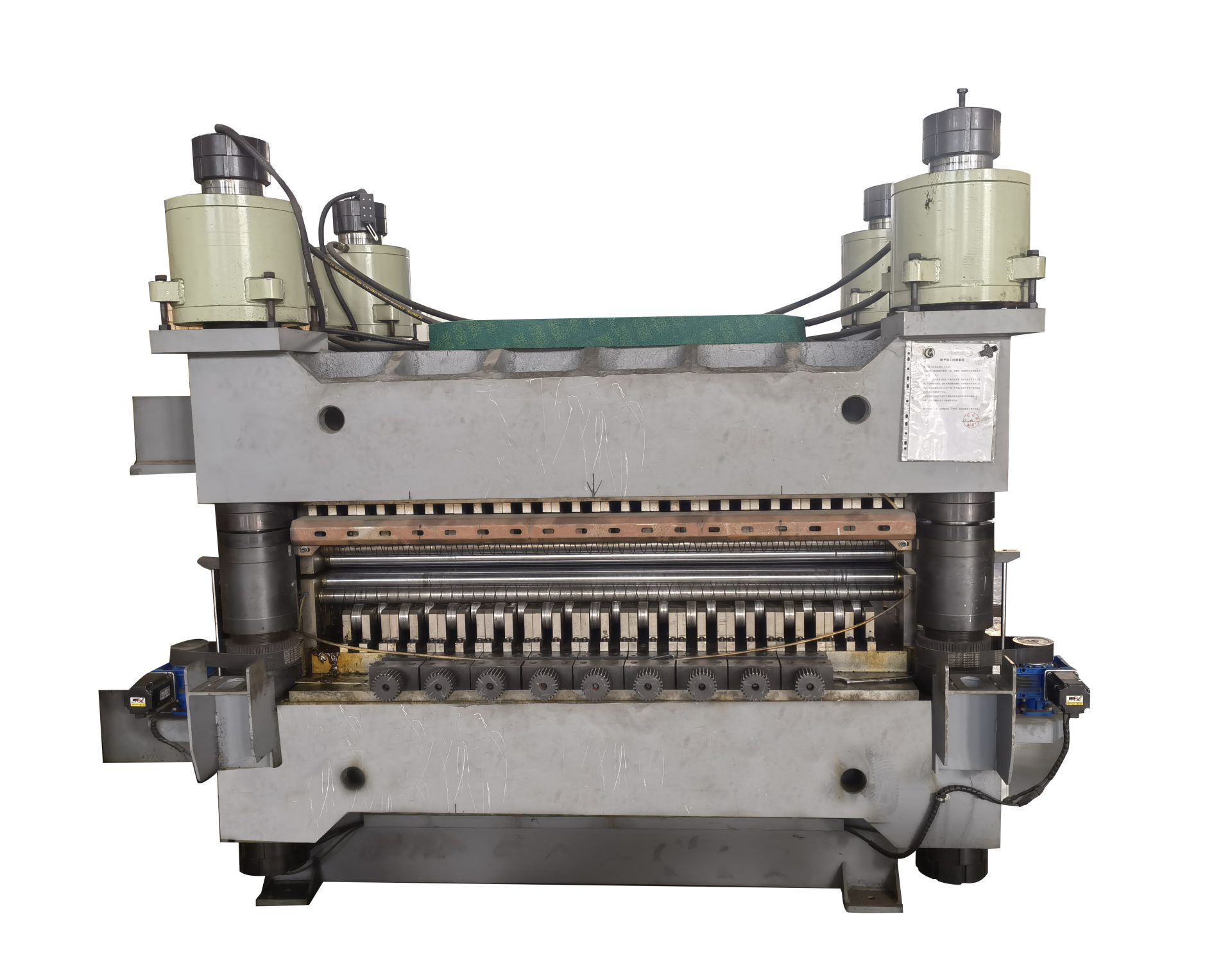

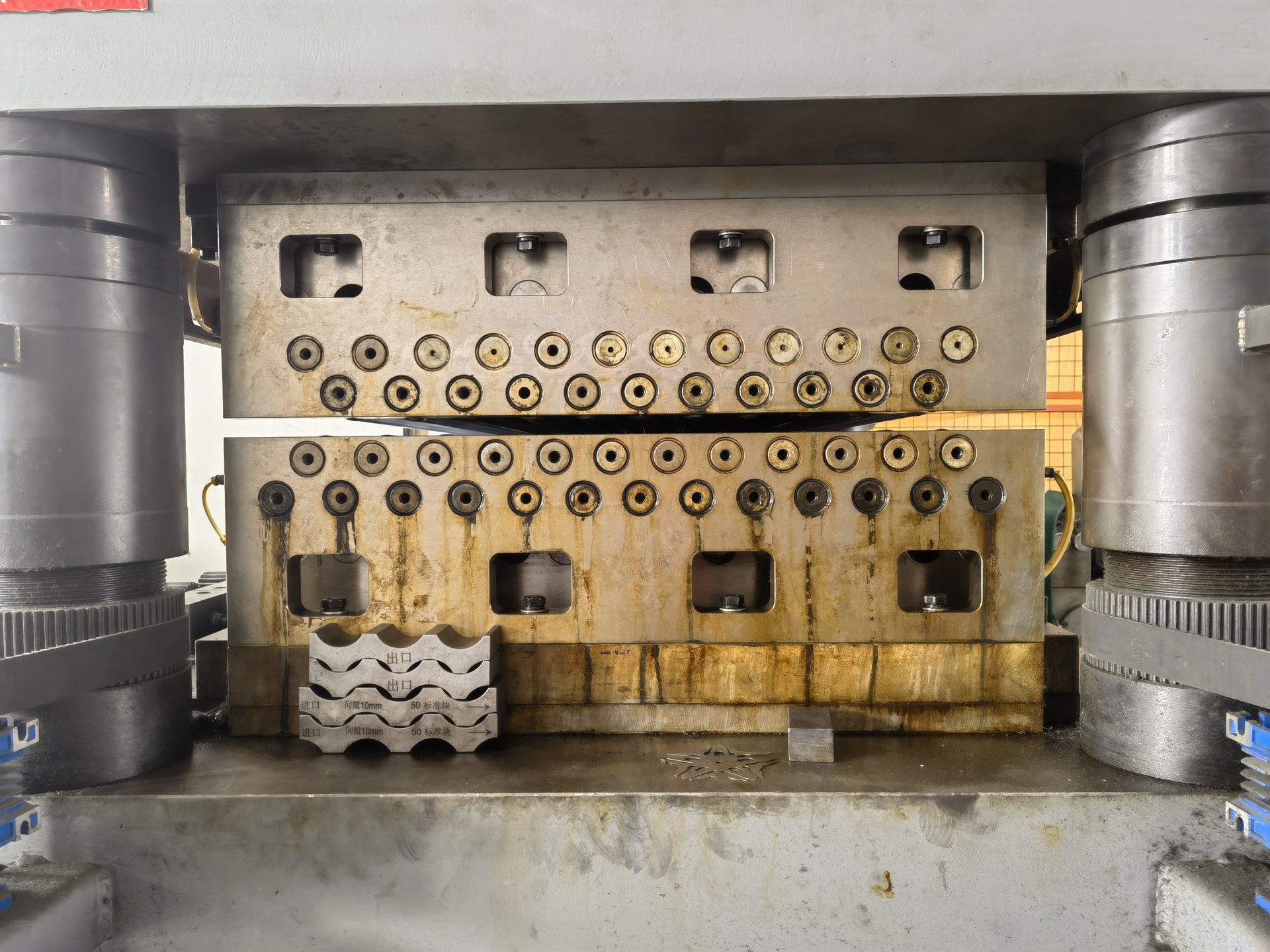

1 There are a large number of leveling rolls and they are closely arranged: 32/40/50/63/80 series 19 rollers; 100 series 17 rollers; 125 series 15 rollers; 160 series 13 rollers. ect.

2 The diameter of the straightening roller is obviously 50% smaller than that of the mechanical parallel roller straightening

machine, and the arrangement is also very tight. A large number of staggered

3 The arrangement is also very tight, a large number of staggered supporting rollers ensure that the leveling roller does not bend and deform when stressed.

4 The strong hydraulic pressure keeps the gap (mechanical dead limit) between the upper and lower rollers unchanged all the time.

5 The three-beam hydraulic press structure with good rigidity reduces the overall deformation degree of the machine to the minimum when it works.

6 The space on the right side of the equipment is open for easy cleaning, maintenance and replacement of the leveling roller

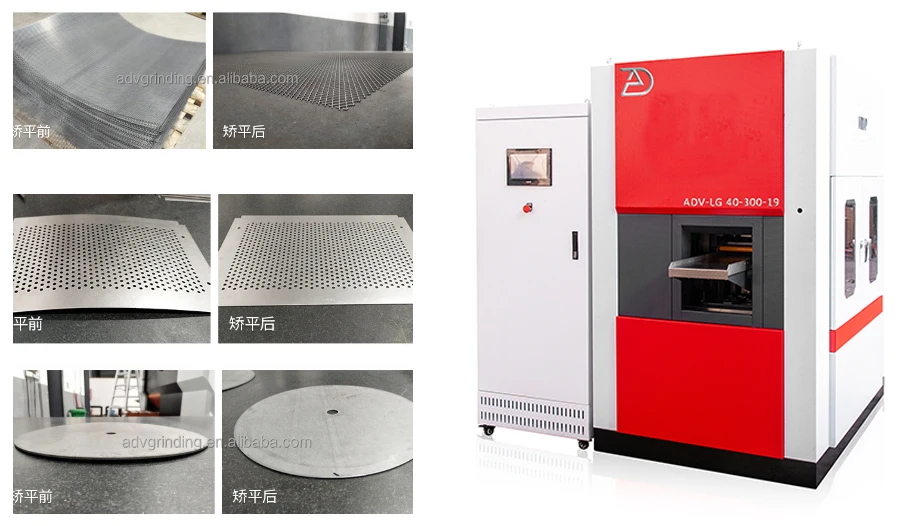

7 New energy-saving, environment-friendly and low-carbon plastic processing equipment for metal plates and plane parts

Machine Parameters

Table for leveled width range of 40 series (Material Q235/yield strength 235Mpa)

|

No

|

Model

|

ADV-LG 40-500-19

|

ADV-LG 40-1000-19

|

ADV-LG 40-1300-19

|

|

1

|

Roller diameter

|

40mm

|

||

|

2

|

Roller number

|

19

|

19

|

19

|

|

3

|

Nominal leveled width

|

500mm

|

1000mm

|

1300mm

|

|

4

|

Rated plate thickness

|

0.6-1.8mm

|

||

|

5

|

Max. plate thickness

|

3.6mm

|

||

|

6

|

Leveled precision

|

K

|

||

|

7

|

Applicable

|

Tape coiling, strip steel, sheet metal, etc

|

||

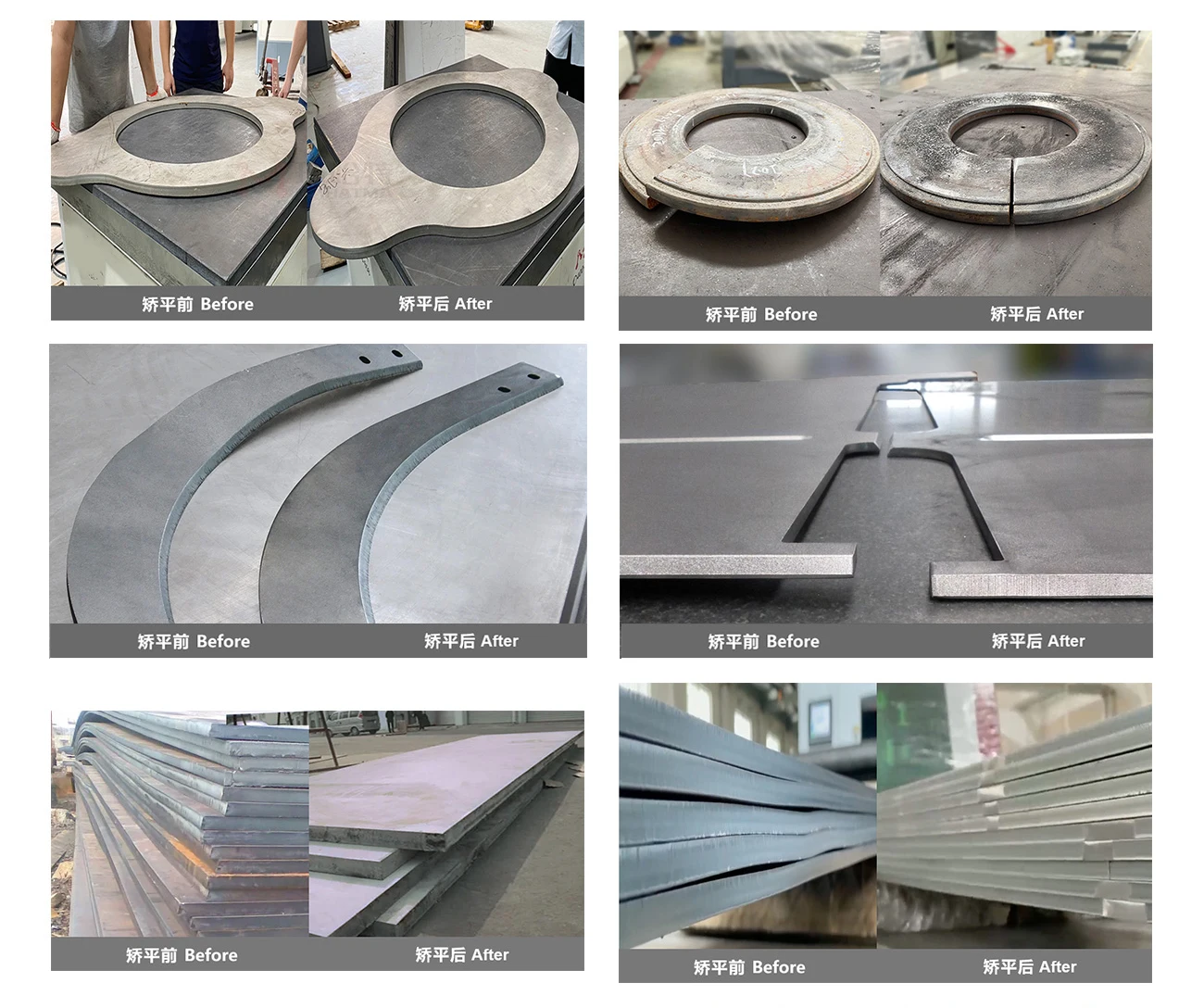

Application industry and sample

CNC sheet leveling machine is used in machining industry, aerospace, automobile manufacturing industry, communication equipment industry, medical equipment industry, laser cutting workpiece industry, etc.

More Info

Machine principle

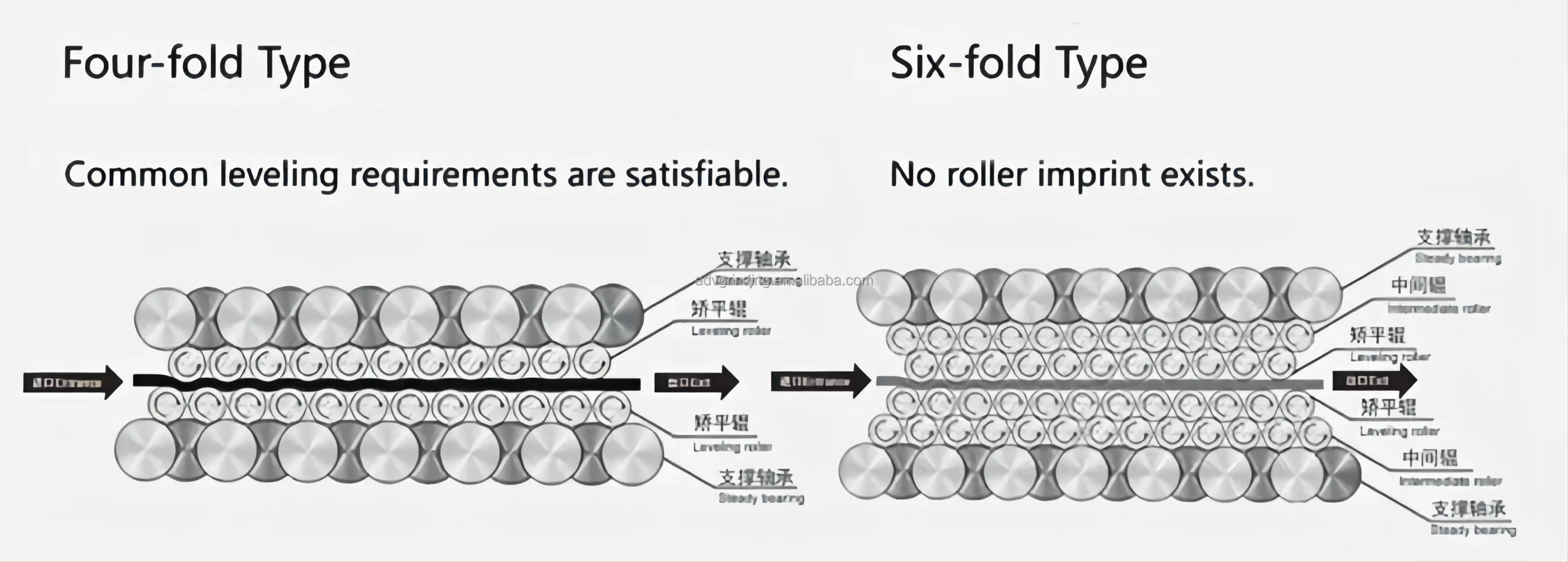

The leveling machine adopts a row of intermediate rollers installed between the upper and lower rows of leveling work rollers and the support bearings (wheels), forming a double or triple roller structure at the upper and lower levels, with a total of four or six layers. The rollers are arranged in a staggered manner, and the amount of bending can be controlled by the electronic control system. Through repeated bending of the leveling rollers, the metal surface tends to be flat.

Send Inquiry

SUBSCRIBE

NEWSLETTER

click here to leave a message