Protective Film Laminating Machine

Product Video

Product Description

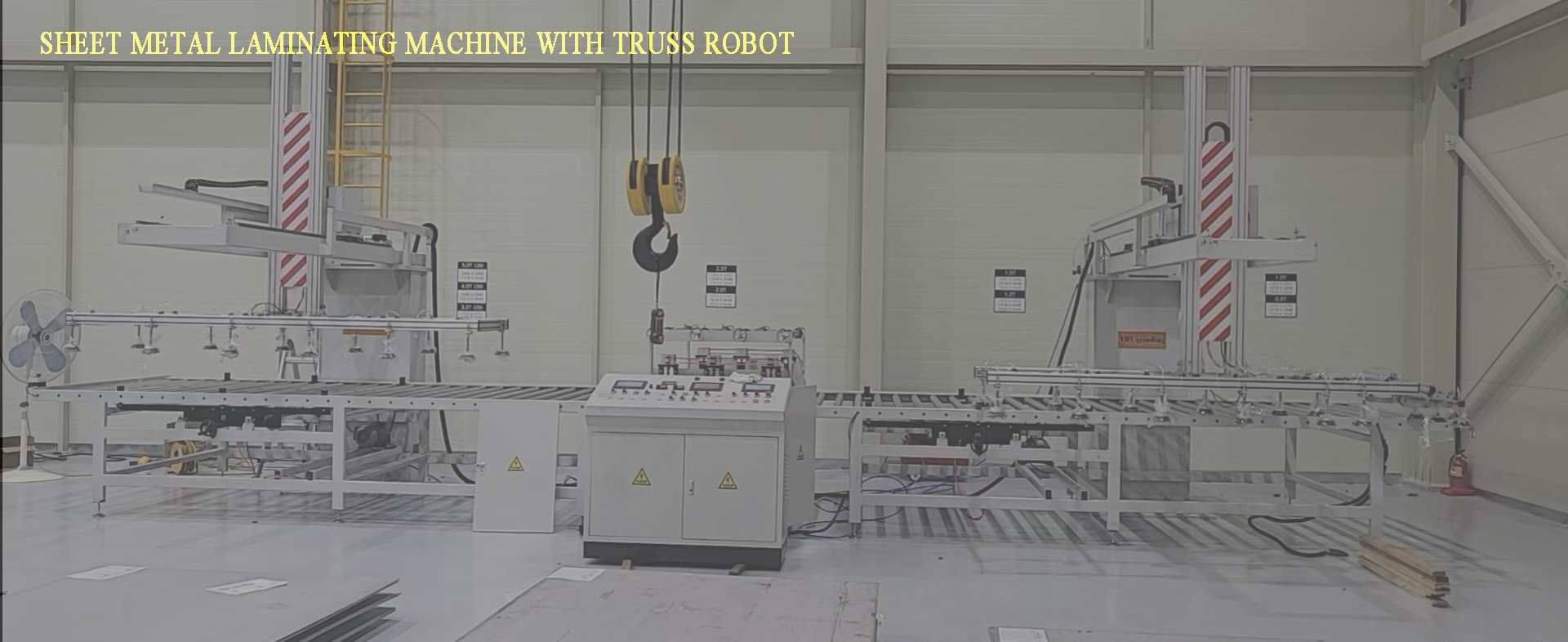

Laminating machine with automatic loading and unloading:

Equipment description:

2. The frame is welded by the national standard 125×125H steel;

3. Independent control cabinet, touch screen, extremely simple operation, manual and automatic switching at

will, flexible and convenient;

4. Programmable PLC, controller and infrared sensor accurately control the servo motor with planetary reducer and pneumatic components to automatically complete a series of actions such as position detection, feeding, filming, and cutting of the sheet.Make the mechanical operation more humane.

Machine Parameters

|

Product name

|

Multifunctional flat automatic laminating machine

|

|

Voltage/power

|

380V 4KW

|

|

Packaging material

|

plastic, metal, Glass,wood

|

|

Running speed

|

5-20 m/min

|

|

Cutting blade

|

Tungsten steel knife/Nickel wire

|

|

Processing board width

|

Available 1250mm/1500mm wide

|

|

Processing board thickness

|

0.5-30 mm

|

|

Processing board length

|

800-3500 mm

|

|

power rack length

|

4500 mm

|

|

unpowered material rack length

|

2500 mm

|

|

Upper and lower rubber roller diameter

|

120 mm

|

Application industry and sample

Used to coat flat metal plates (aluminum, copper, stainless steel, etc.), glass, MDF plates, wood board and other materials

More Info

Equipment advantages:

1. After the machine is loaded, the distance between the two materials is automatically adjusted;

2. Cutting device, adjustable speed, easy blade replacement;

3. The equipment is suitable for single-sided and double-layer filming of the sheet, and it is automatically cut;

4. Precise induction, cutting accuracy of ±1mm.

5.intelligent control system,interactive man-machine interface

6. Reverse function before and after laminating

7. Low noise operation, high sensitivity

8. All parts of the machinery adopt the products of famous and excellent manufacturers

9. Can work in cold and low temperature conditions

Send Inquiry

SUBSCRIBE

NEWSLETTER

click here to leave a message