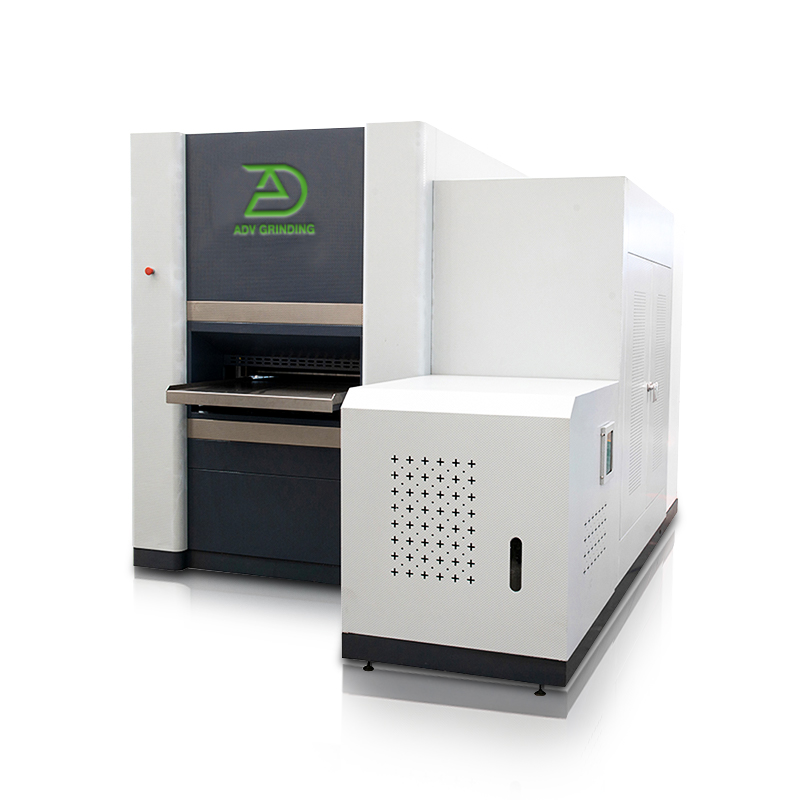

ADV LG63

Product Description

ADV LG63 Series Servo Electric Leveling Machine

ADV machinery specializes in the production of servo electric leveling machines with dynamic compensation functions, providing customers with professional sheet metal leveling solutions with a complete series, which can process plates with a width of 0-2100mm and a thickness of 0.1-30mm. It can precisely straighten linear guide rail, rack, square steel, flat steel, angle steel and other section steels (before and after heat treatment)

Machine Parameters

| No | Model | ADV LG63-500 | ADV LG63-800 | ADV LG63-1300 | ADV LG63-1600 |

| 1 | Roller diameter | 63mm | |||

| 2 | Roller number | 19 | |||

| 3 | Nominal leveled width | 500mm | 800mm | 1300mm | 1600mm |

| 4 | Rated plate thickness | 1.2-4.0mm | 1.2-4.0mm | 1.2-4.0mm | 1.2-4.0mm |

| 5 | Max. plate thickness | 10mm | |||

| 6 | Leveled precision | H/K | |||

| 7 | Applicable | Tape coiling, strip steel, sheet metal, etc | |||

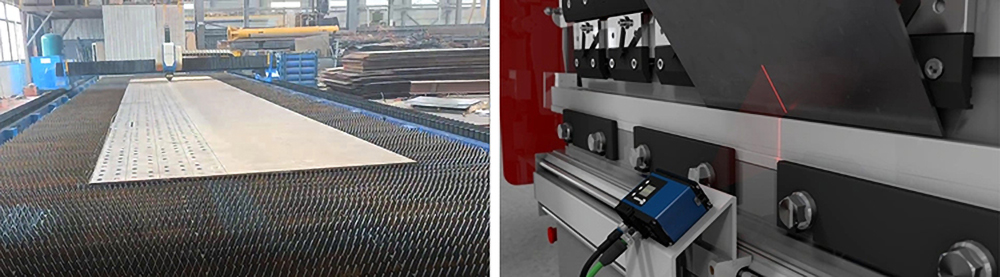

Application industry and sample

Common application scenarios:

Before laser cutting and bending of sheet metal

Automotive manufacturing and aerospace

Electronics and Home Appliances

More Info

Features of electric high-precision leveling machine

1. High-quality support rollers with long service life

Reasonable number of support rollers, strong support, can repeatedly achieve stable leveling effect, and improve the service life of support rollers

2. High degree of electric automation

The leveling machine production line is controlled by high-precision system and fully automatic positioning servo system to ensure automation and high-efficiency production

3. Welded steel structure roller frame, anti-twist

It can level high-strength steel. The upper and lower roller frames are connected by four columns, which is different from the traditional frame beam structure to ensure overall high rigidity

4. Leveling roller surface polishing treatment

Ensure that the surface of the parts is not damaged during the leveling process

5. Operating system, more intelligent

Visual operation, providing precise settings, the equipment is equipped with a 10-inch touch screen as standard, the operation interface is simple, professional program is quickly set, the data display range is 0.01mm, and remote service is optional

6. Machine tool design, customizable

One side is equipped with a large movable door with an observation window, which is easy to contact and observe the internal mechanism of the machine tool. The operation is simple, and the operation button is installed at the inlet and outlet. The body color and the position of the operation panel can be customized as needed