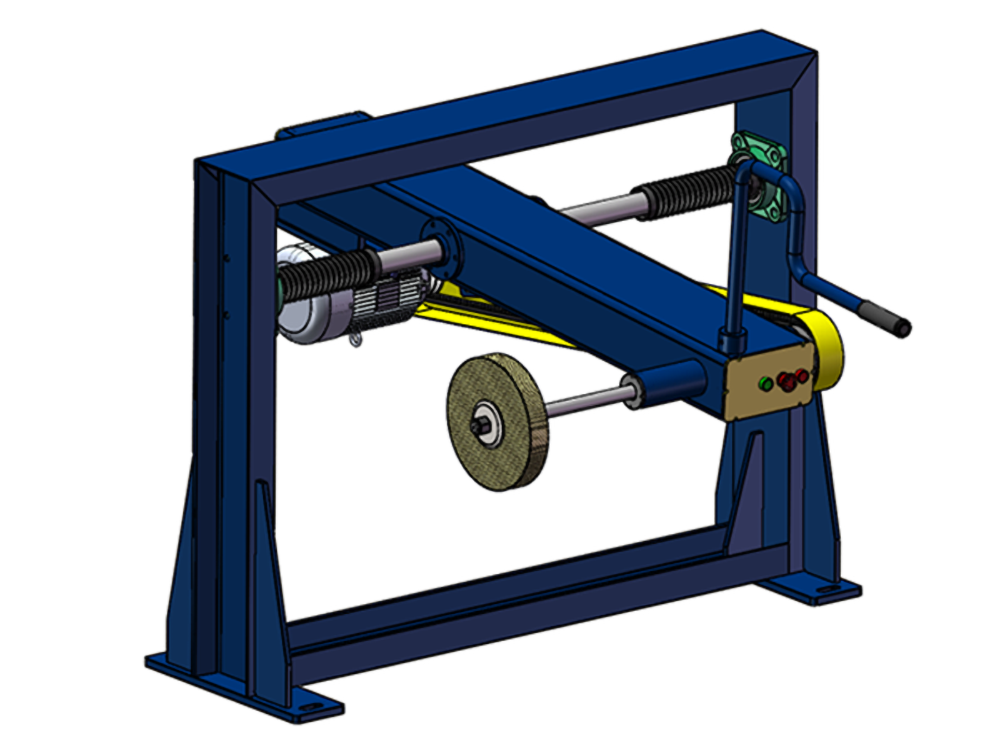

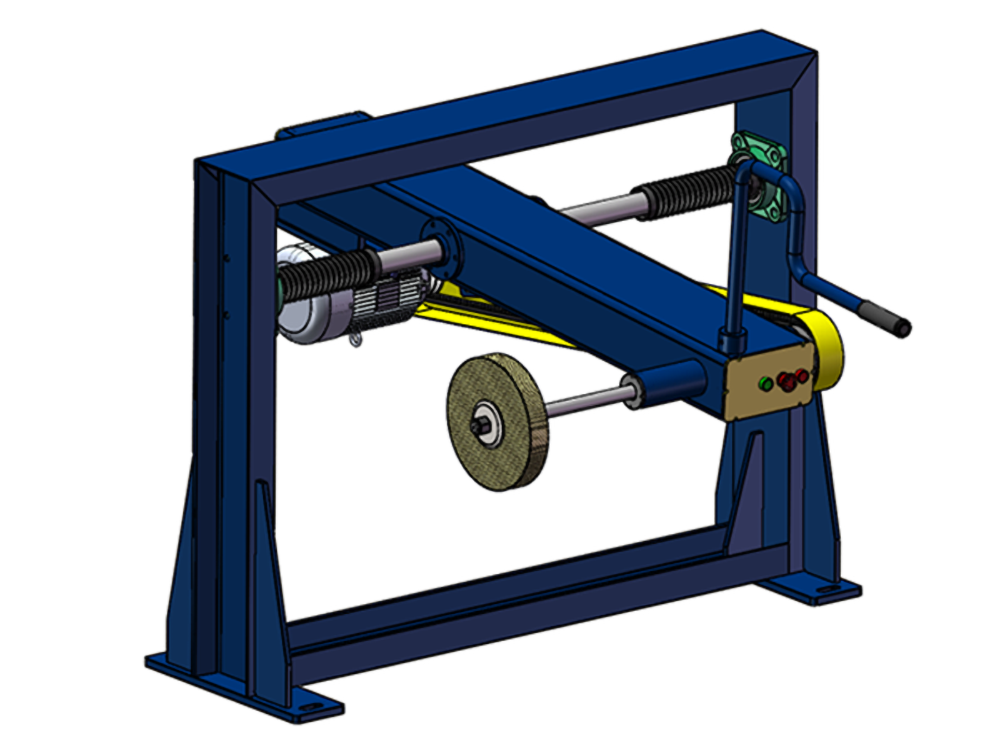

Grinding System:

It is transferred to the grinding head through the rotation of the V-belt, and directly drives the polishing wheel to rotate and polish the workpiece at high speed.

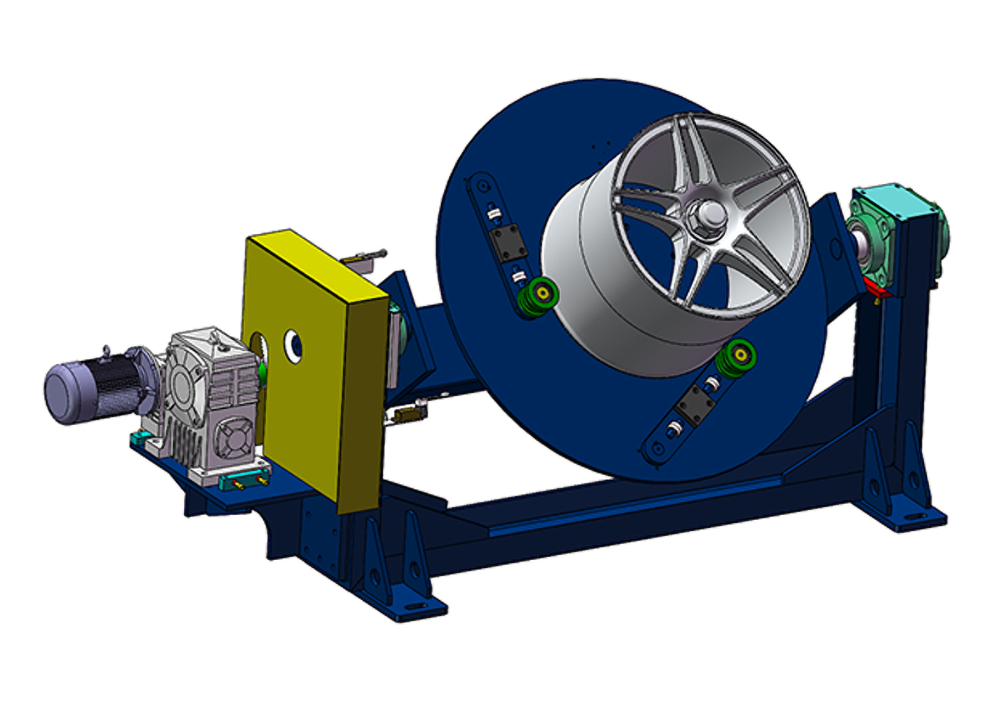

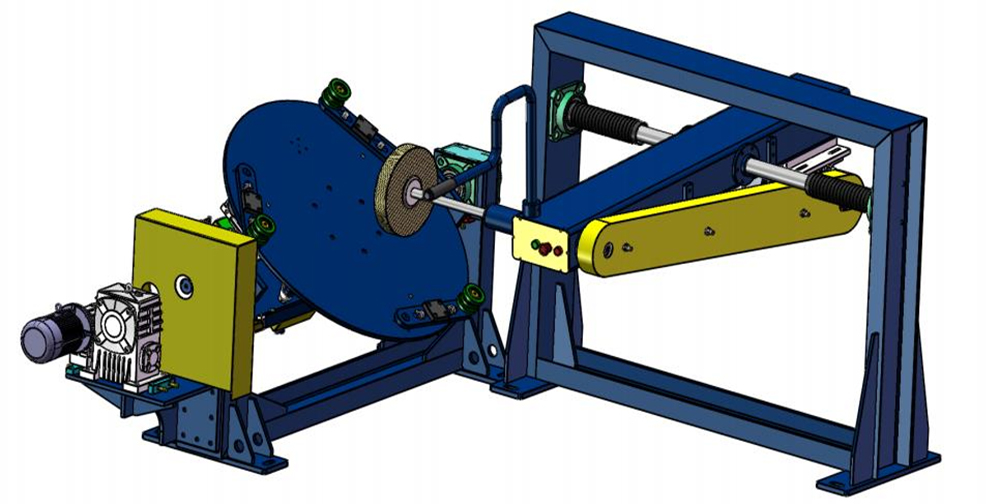

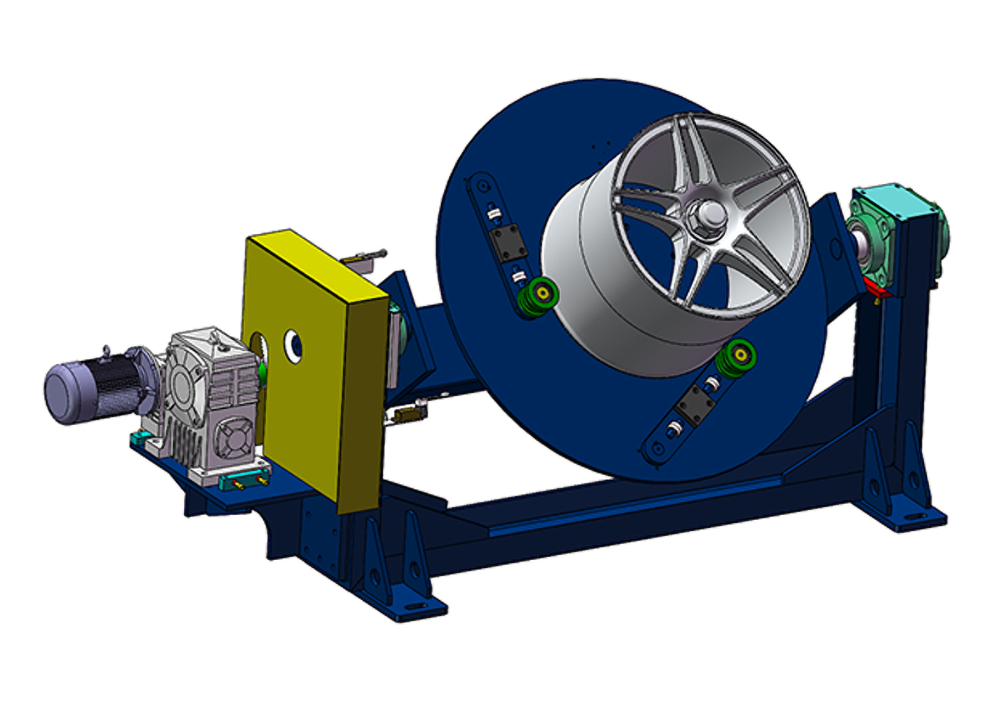

Workpiece rotation turning over system:

This specifically designed wheel rim polishing machine can retreat tire, burr removing, and grinding to a high mirror finish. It solves the problem of poor surface grinding and the high labor costs of manual polishers. It is a good tool for polishing car and truck wheels.

The equipment mainly consists of one set of grinding heads, one set of manual feeding of grinding heads, one set of workpiece rotation system, one set of workpiece flipping system, one set of pneumatic fixtures, one set of electrical controls, one set of pneumatic system, one set of automatic waxing system(Optional).

|

No

|

Item

|

Specification

|

|

1

|

Model

|

ADV 408

|

|

2

|

Buffing wheel motor power

|

4kw

|

|

3

|

Rim diameter

|

12″-36″

|

|

4

|

Buffing wheel size

|

300*50*32 mm

|

|

5

|

Rotating Table Motor Power

|

0.75 kW

|

|

6

|

Turning over motor power |

0.75 kW

|

|

7

|

The Gas Source

|

0.6 m³/ h ; 0.4 ~ 0 6Mpa; pipe:8*5mm

|

|

8

|

Machine size

|

2200*1800*1600 mm

|

|

9

|

Machine weight

|

1400 kg

|

Grinding System:

It is transferred to the grinding head through the rotation of the V-belt, and directly drives the polishing wheel to rotate and polish the workpiece at high speed.

Workpiece rotation turning over system:

Polishing by constantly adjusting the angle of the workpiece to get the finished products

Equipment features:

1. Workpiece diameter range: 12″-32″ with or without tires,with a 3” bore air cylinder clamp.

2. The turntable rotates about 1 to 30RPM and the speed controller driver controls it.

3. The polishing grinding head power is 4kw, which can realize forward and reverse rotation

4. The machine consists of hosts, a standard polishing head, an electric control system, a pneumatic system, and a rotating table.