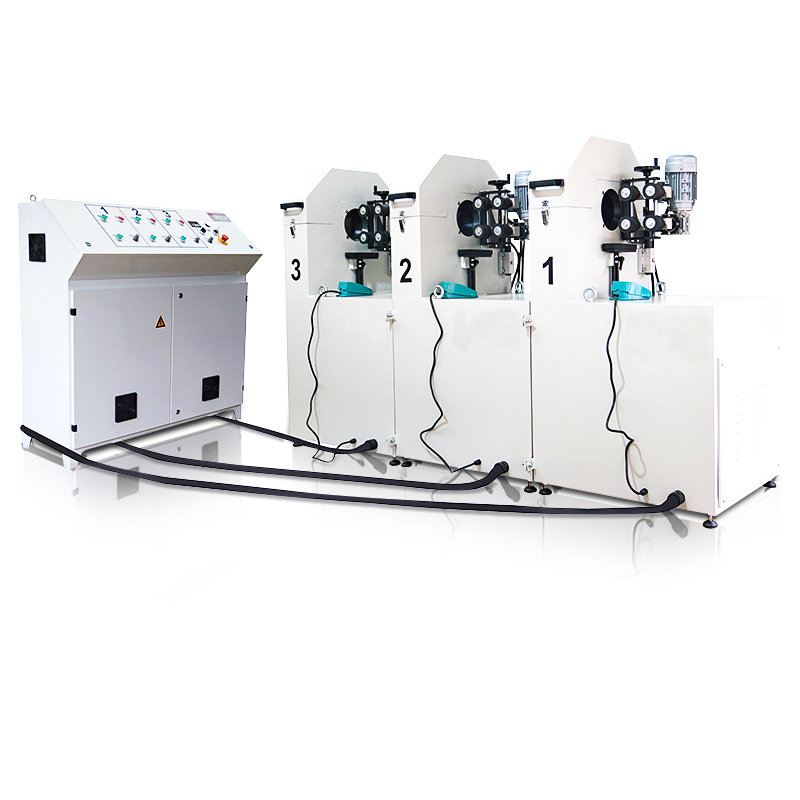

ADV 108-H3

Product Video

Product Description

Machine Parameters

|

No

|

Item

|

Specification

|

|

1

|

Available tube diameter

|

Ø10 – Ø 110 mm

|

|

2

|

Total motor power

|

12KW

|

|

3

|

Abrasive Belt Motor power

|

2.2*3KW

|

|

4

|

Rotating speed of main motor

|

1200-3300rpm

|

|

5

|

Speed of abrasive belt

|

7.8-18m/s

|

|

6

|

Transfer wheel motor power

|

1.5*3kw

|

|

7

|

Feeding system motor power

|

3x 0.12KW

|

|

8

|

Speed of feeding

|

0.7-4m/min

|

|

9

|

Size of abrasive belts

|

(2)940 x 50mm

|

Application industry and sample

Application Industries:

1. Furniture industry: steel table tube, steel chair tube, steel bed tube, steel towel rack, etc.

2. Construction industry: steel guardrails, steel doors, steel handrails and steel windows, etc.

3. Public facilities industry: flagpoles, outdoor sports equipment, bus and subway handrails, etc.

More Info

The three-station planetary round tube polishing machine is a highly efficient equipment specially used for drawing and polishing the surface of round tubes. Its main advantages include the following aspects

Multi-station design: The three stations run simultaneously, which can continuously process the round tubes, greatly improving production efficiency.

Planetary rotation: The planetary rotation structure is adopted, and the abrasive belt rotates around the round tube to ensure that the processing surface is uniform and there is no dead angle.

Uniform grinding: The planetary design ensures that each abrasive applies pressure evenly, making the surface treatment of the round tube smoother and scratch-free.

Adjustable coarseness and fineness: Supports abrasive belts of different girts to meet various needs from rough grinding to fine polishing.

Applicable to various materials: Suitable for polishing of various metal materials such as stainless steel, aluminum, copper, iron, etc.

Adapt to different pipe diameters: The spacing of the equipment abrasive belt can be adjusted to adapt to round tubes of different diameters, expanding the scope of use

High degree of automation, reducing manual intervention, improving safety and production efficiency, and reducing the labor intensity of operators.