ADV -408

Product Video

Product Description

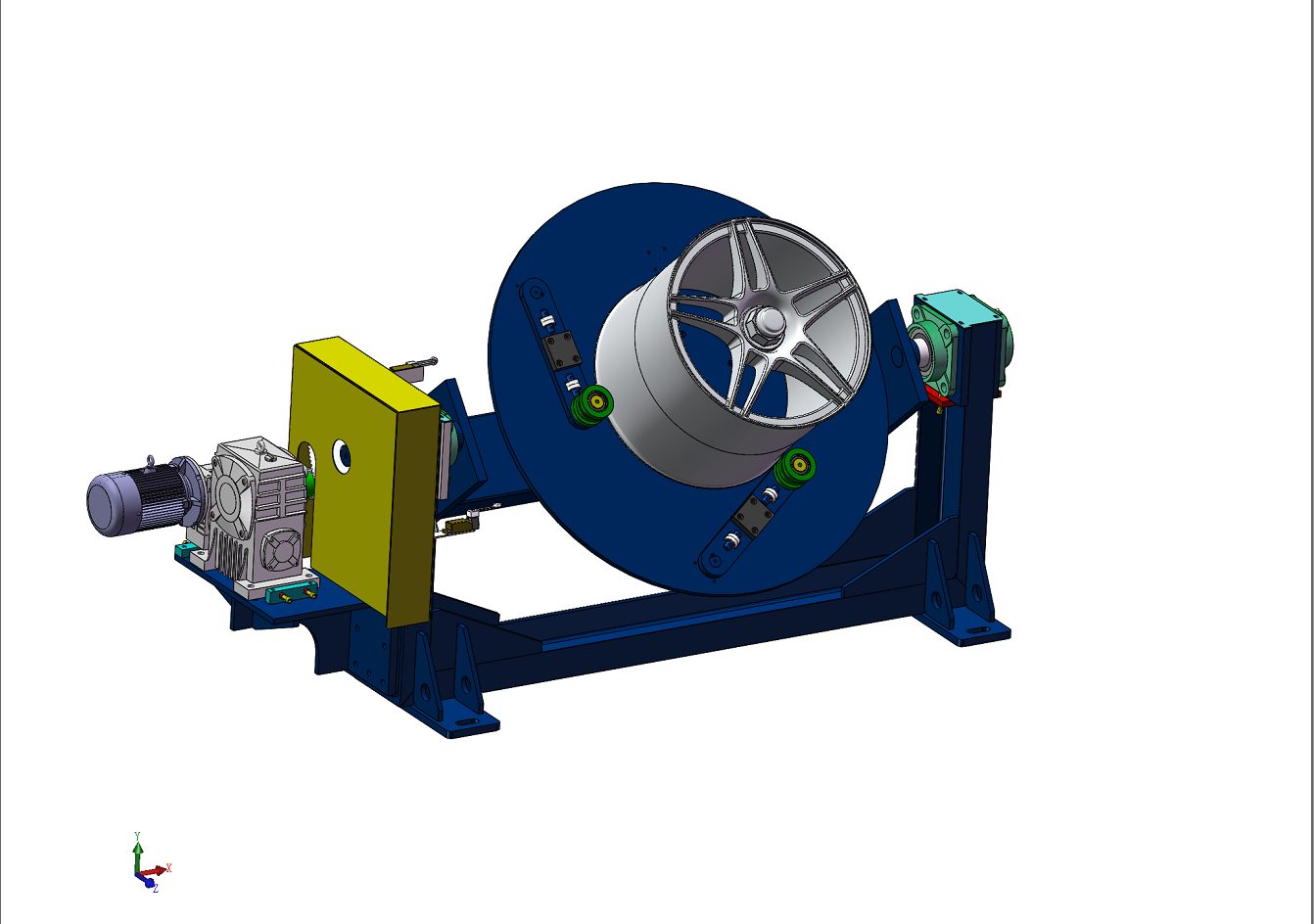

1.The machine is mainly used for polishing aluminium alloy wheel.The inner and outer walls grinding and polishing.

2.Workpiece diameter range: 12″-32″ with or without tires,with a 3” bore air cylinder clamp.

3.The turntable rotates about 1 to 30RPM and it controlled by the speed controller driver.

4.The polishing grinding head power is 4kw, which can realize forward and reverse rotation

5.Machine consists of hosts, standard polishing head, electric control system, pneumatic system and rotaring table.

3.The turntable rotates about 1 to 30RPM and it controlled by the speed controller driver.

4.The polishing grinding head power is 4kw, which can realize forward and reverse rotation

5.Machine consists of hosts, standard polishing head, electric control system, pneumatic system and rotaring table.

Machine Parameters

|

No

|

Item

|

Specification

|

|

1

|

Model

|

ADV 408

|

|

2

|

Buffing wheel motor power

|

4kw

|

|

3

|

Rim diameter

|

12″-32″

|

|

4

|

Buffing wheel size

|

300*50*32 mm

|

|

5

|

Rotaring Table Motor Power

|

0.75 kw

|

|

6

|

Turning over motro power

|

0.75 kw

|

|

7

|

The Gas Source

|

0.6 m³/ h ; 0.4 ~ 0 6Mpa; pipe:8*5mm

|

|

8

|

Machine size

|

2200*1800*1600 mm

|

|

9

|

Machine weight

|

700 kg

|

Application industry and sample

Application products:

Aluminum truck and Car wheel rims

Application Industries:

Truck Dealers: Boost resale value of used vehicles and build customer loyalty. Fleets: Improve fleet safety, strengthen fleet pride, and reduce wheel-end maintenance costs. Commercial Tire Shops: Expand customer services and add a new revenue stream. Retail Shops: Compliment chrome shop sales and reduce labor costs.

More Info

ADV 408 Turck and car alloy wheel polishing machine

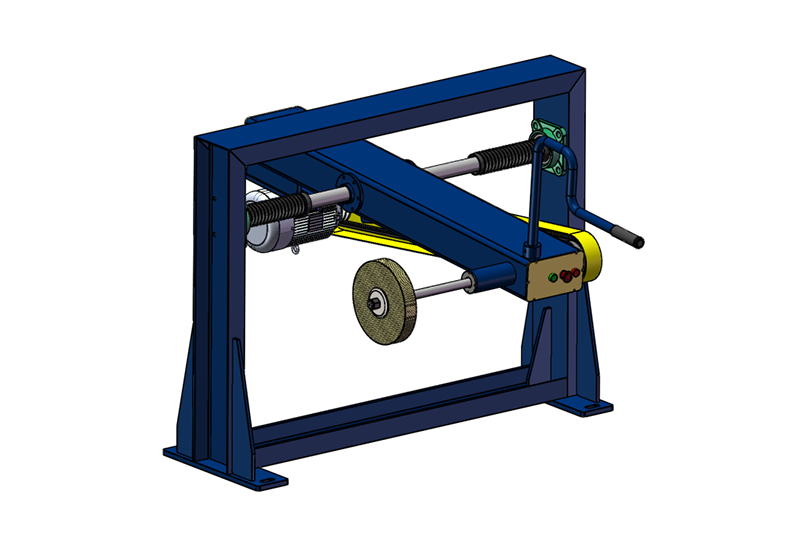

The grinding head moves back and forth by manual control, and the hub rotates and turns over on the turntable. The surface gloss of the workpiece is increased by grinding the surface of the material.

Grinding system:

It is transferred to the grinding head through the rotation of the V-belt, and directly drives the polishing wheel to rotate and polish the workpiece at high speed.

Workpiece rotation turning over system

Polishing by constantly adjusting the angle of the workpiece to get the finished products

Send Inquiry

SUBSCRIBE

NEWSLETTER

click here to leave a message