ADV 508-HRW

Product Video

Product Description

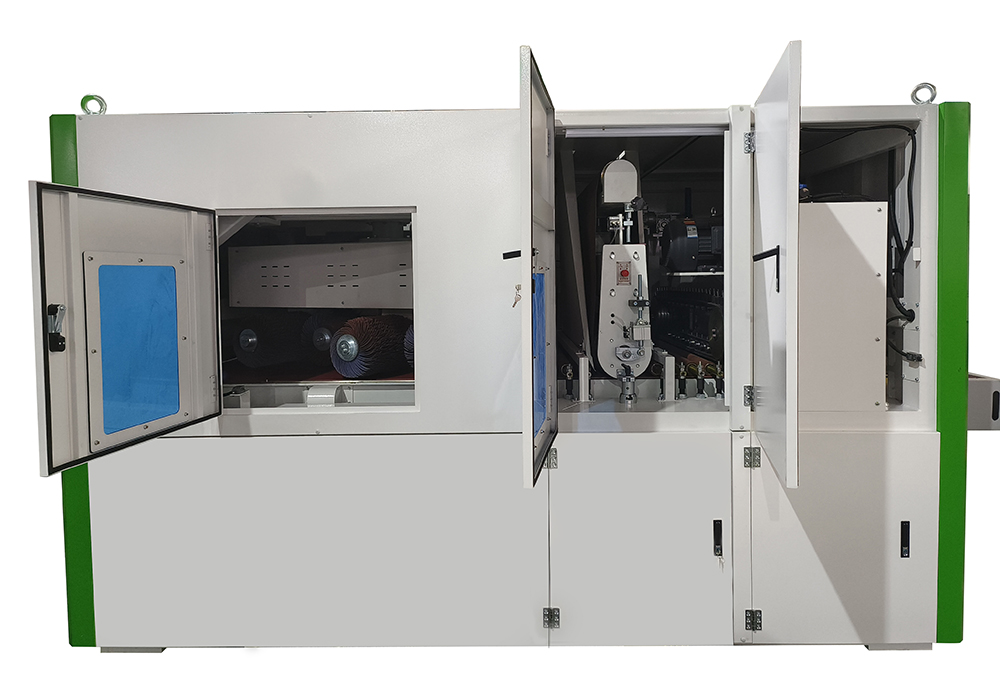

ADV 508-HRW Heavy slag removal, deburring and edge rounding machine

Heavy Slag removal from carbon steel plates usually refers to the removal of welding slag or cutting slag produced during welding or cutting. These slags can adhere to the surface of the steel plate, affecting the aesthetics and surface quality. The HRW series deburring machine can remove surface slag and perfect rounding on metal in one time.

Machine Parameters

|

No

|

Item

|

Specification

|

|

1

|

Model

|

ADV 508-HRW1300

|

|

2

|

Available width

|

30-300mm

|

|

3

|

Available thickness

|

0.5-100mm

|

|

4

|

Minimum Machinable Size

|

30*30mm

|

|

5

|

Belt size

|

2000*1320mm

|

|

6

|

Conveying speed

|

0.5-8m/min frequency control

|

|

7

|

No.1 motor power

|

4kw*2(cleaning hammer or sand block)

|

|

8

|

No.2 motor power

|

22kw(abrasive belt)

|

|

9

|

No.3 motor power

|

4kw*4(rotary brush)

|

|

10

|

Vacuum adsorption motor power

|

18.5 kw(optional)

|

|

11

|

Total motor power

|

73.69kw

|

More Info

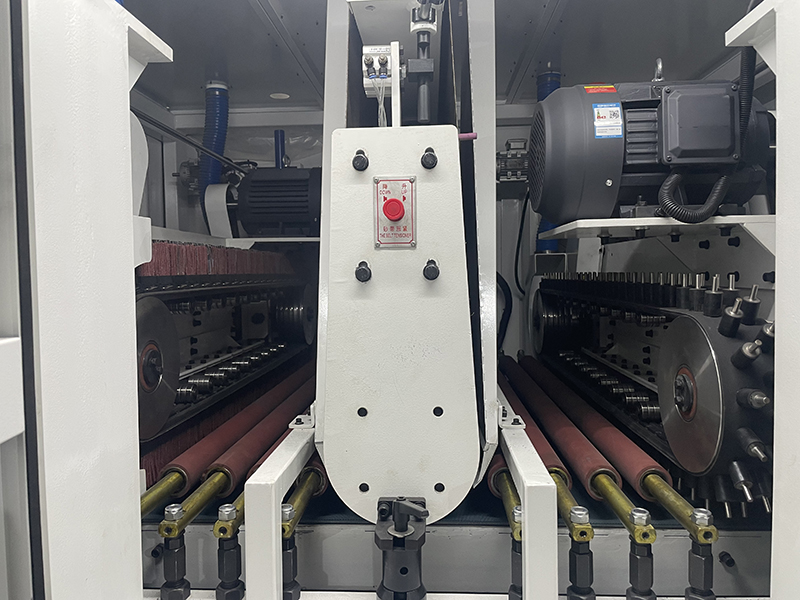

HRW internal station diagram:

Why should we remove slag?

Improve surface quality: Slag removal can remove welding slag, cutting slag and other undesirable substances generated during welding, cutting or processing, making the surface of the carbon steel plate smoother and neater, and improving the appearance quality and look and feel of the product.

Enhanced anti-corrosion performance: Removing surface slag can reduce the possibility of corrosion. The slag generated during the welding or cutting process may form tiny cracks or depressions on the surface of the steel plate. These cracks and depressions are easily eroded by corrosive media. Removing the slag can reduce these hidden dangers.

Improve coating adhesion: Slag removal can ensure that the surface of the steel plate is clean and the coating can better adhere to the surface, improving the adhesion and durability of the coating.

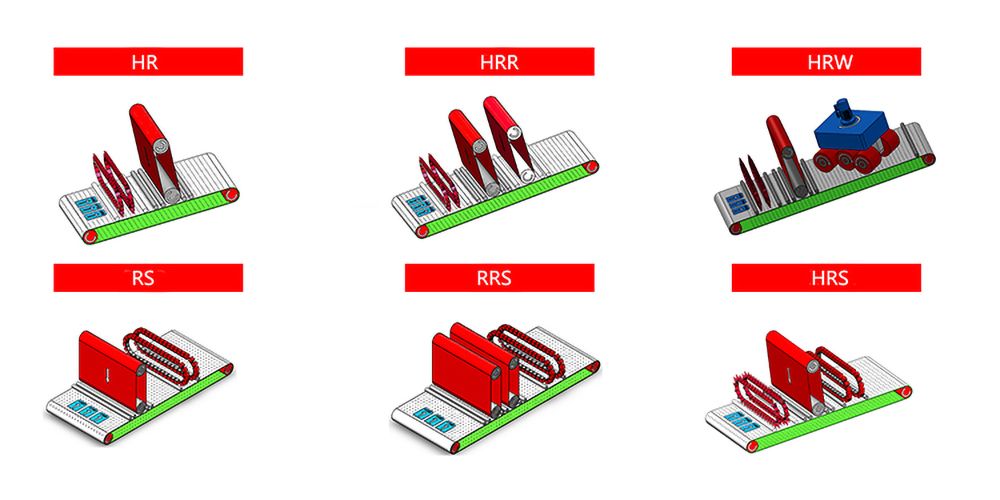

HR combinations that can be customized according to customer requirements(H=Hammer station, R=Belt station, W=Rotary brush station, S=Sand block station)