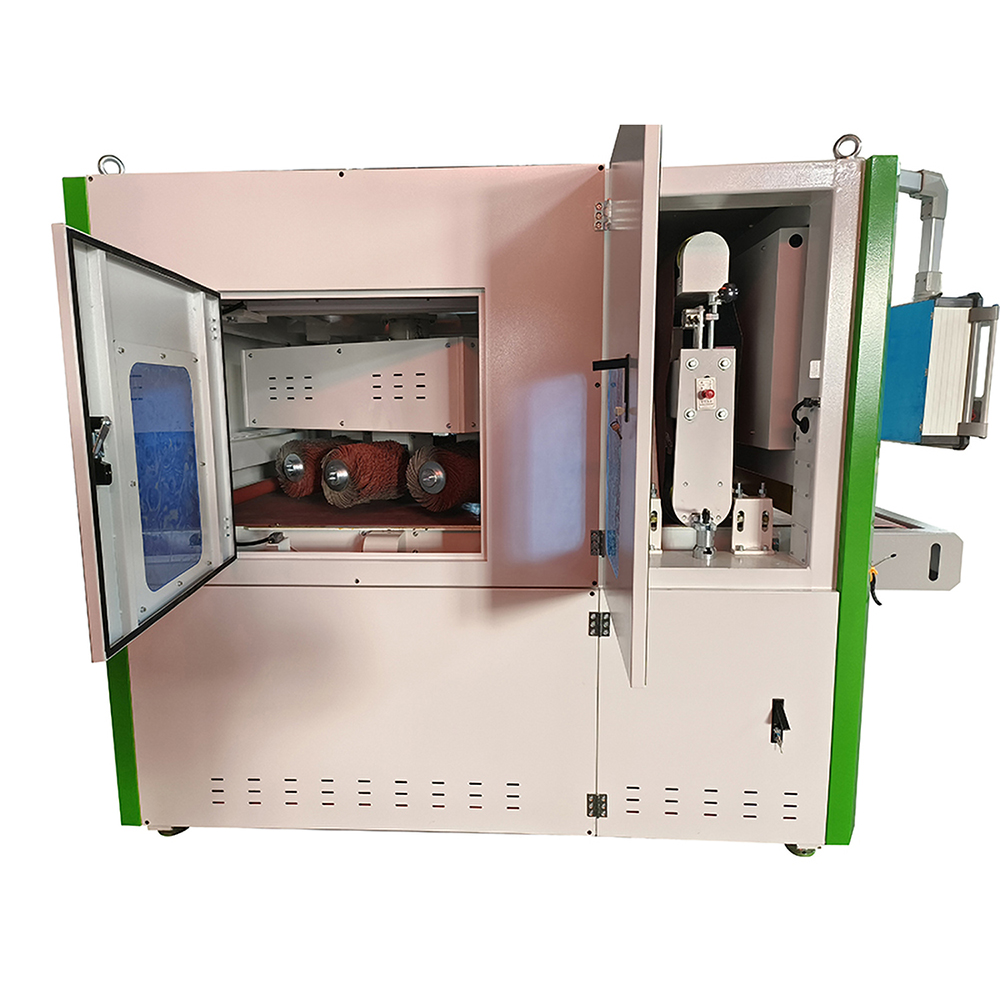

ADV 508-RW sheet metal deburring and edge rounding machine

Product Video

Product Description

Tips:PLC sheet metal deburring machine for laser cutting parts

1.In any cutting, drilling, laser, mill, and other machining processes, burrs, hot slag, and scum will be produced at the edge of the workpiece, so it is particularly important to choose the correct deburring machine.

2.The ADV 508-RW series is used for deburring, edge rounding, and laser oxide removal of various sheet metal parts.(Abrasive belt+Rotary brush).

2.The ADV 508-RW series is used for deburring, edge rounding, and laser oxide removal of various sheet metal parts.(Abrasive belt+Rotary brush).

3.The standard available width is 630mm, 800mm, 1000mm, 1100mm, 1300mm, 1400mm, or customized.

4.The deburring machine can process parts with a minimum size of 30mm*30mm(with a vacuum table).

Machine Parameters

|

Model

|

ADV 508-RW630

|

ADV 508-RW800

|

ADV 508-RW1100

|

ADV 508-RW1300

|

|

Effective processing width

|

30-630 mm

|

30-800 mm

|

30-1100mm

|

30-1300mm

|

|

Processing thickness

|

0.5-100mm

|

0.5-100mm

|

0.5-100mm

|

0.5-100mm

|

|

Minimum Machinable Size

|

30*30mm

|

30*30mm

|

30*30mm

|

30*30mm

|

|

Belt size

|

1900*650mm

|

2000*820mm

|

2000*1120mm

|

2200*1320mm

|

|

Conveying speed

|

0.5-5m/min frequency control

|

|||

|

Number of rotating brushes

|

4

|

4

|

6

|

8

|

|

Belt motor power

|

15kw

|

15kw

|

18.5kw

|

22kw

|

|

Rotary brush motor power

|

1.5kw*2

|

2.2kw*2

|

2.2kw*1/1.5kw*2

|

2.2kw*4

|

|

Conveying motor power

|

1.5kw

|

1.5kw

|

1.5kw

|

1.5kw

|

|

Vacuum adsorption motor power

|

15 kw

|

|||

|

Total motor power

|

36.42kw

|

37.82kw

|

42.12kw

|

49.22kw

|

|

Machine size

|

2800*1550*2150mm

|

2800*2000*2250mm

|

3200*2100*2300mm

|

3500*2150*2250mm

|

|

Machine weight

|

2100kg

|

2650kg

|

3600kg

|

4100kg

|

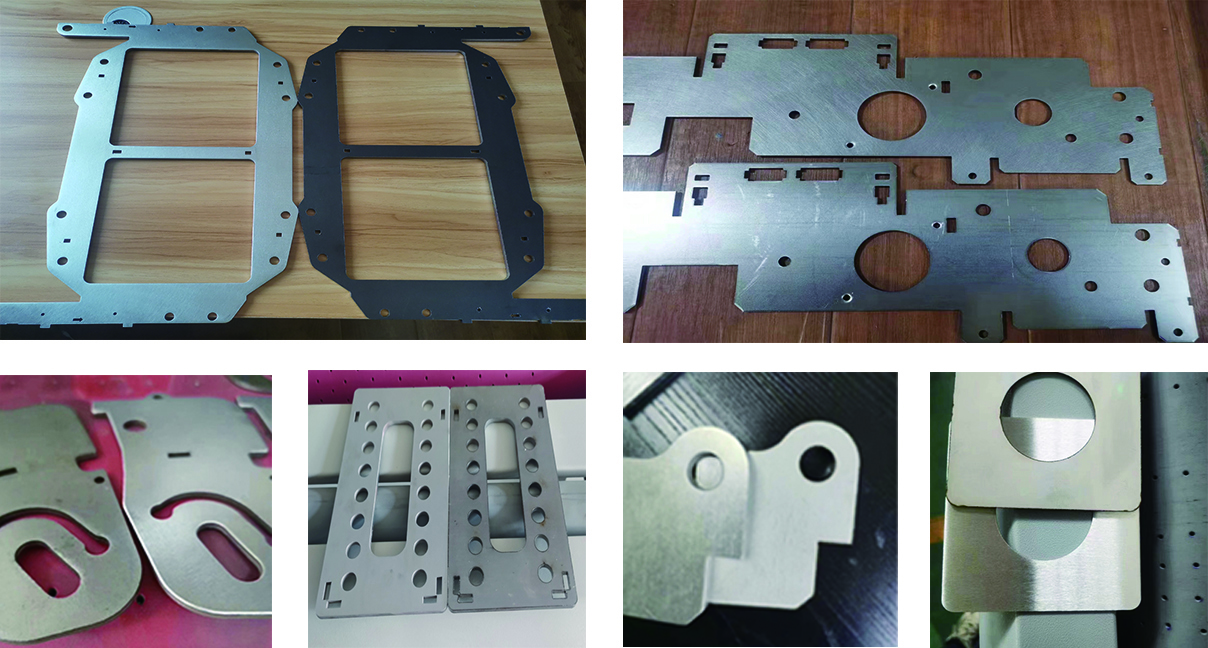

Application industry and sample

burr,shap edge of NCT. die stamping. cutting etc

Small slag. soft burr produced by laser plasma, flame

ADV 508-RW Metal deburring machine are widely used in manufacture Billboard, Signs, Advertising, Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters, Sheet Metal Processing, Metals Components and Parts, Ironware, Chassis, Racks & Cabinets Processing, Metal crafts, metal art ware, elevator panel, hardware, auto parts, Glasses Frame, Electronic Parts, Nameplates, etc.

More Info

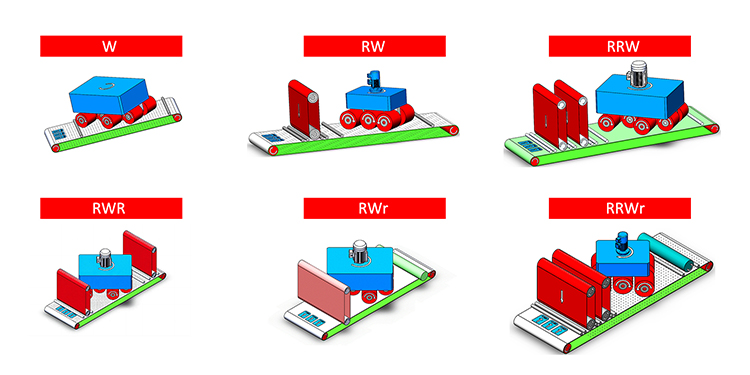

RW combinations that can be customized according to customer requirements

Function of RW series equipment

- Remove silhouette edge hard burr

- Remove cutting slag

- Edge rounding of outside and inside profile more uniforn

- Strong adsorptive force, satisfy smaller parts

- Automatic compensation for abrasive material

- Abrasive replacement remind

- Metal removal oxide layer and surface brushed

Features of RW series equipment

- Replacing inefficient manual grinding of workpieces through type processing

- Finish deburring and edge rounding with one feeding

- PLC touch operation, and the equipment has built-in LED source

- Vacuum or strong magnetic conveying platform, which can process small parts

- Flexible grinding, does not damage the surface of the workpiece

- Optional wet dust collector to absorb dust when working

Send Inquiry

SUBSCRIBE

NEWSLETTER

click here to leave a message